Introducing PCB Manufacturing Service from Microchip USA: A Seamless Solution for Your Circuit Board Needs

More from the Category

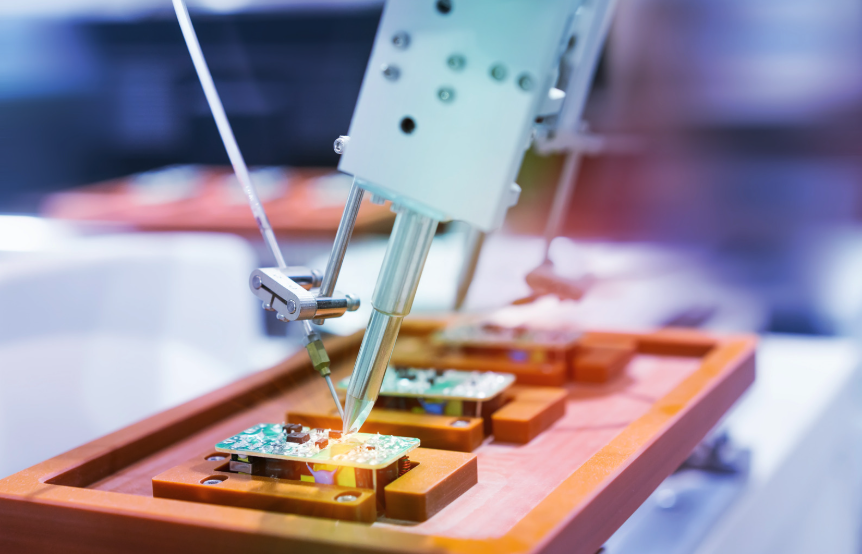

In the rapidly evolving world of electronics, the Printed Circuit Board (PCB) is the foundation of virtually every modern device. Whether you call it a Circuit Board, Bare Board, Printed Wiring Board (PWB), or Circuit Card, its function remains the same: to interconnect electronic components efficiently. Recognizing the critical role of PCBs, Microchip USA has launched its PCB Build Service to offer a streamlined, cost-effective, and high-quality manufacturing process tailored to the needs of engineers and electronics professionals.

What is a PCB?

A Printed Circuit Board (PCB) is a flat board that provides mechanical support and electrical connections for electronic components. Typically made from a non-conductive substrate such as fiberglass (FR4) or composite epoxy, it features thin copper traces that function as electrical pathways. These pathways eliminate the need for traditional wiring, allowing for compact and reliable circuit designs.

PCBs can be classified into three types:

● Single-layer: A basic PCB with components mounted on one side and copper traces on the other.

● Double-layer: Copper traces are on both sides, increasing routing capability.

● Multi-layer: Multiple copper layers stacked together with insulating layers, ideal for high-performance electronics.

These boards are used in everything from consumer gadgets to industrial machinery, medical devices, and high-frequency communication systems.

Designing and Defining PCBs

The design and manufacturing of a PCB involve several crucial steps that ensure performance and reliability. Here’s a breakdown of the process:

CAD Design & Automating the Blueprint

PCB design begins with Computer-Aided Design (CAD) software, which engineers use to create the board layout. The software helps define circuit paths, layer stack-ups, and pad placements while automating error-checking to minimize potential issues before fabrication.

Selecting Materials & Metallic Finishes

Different applications require different PCB materials. High-frequency applications may use PTFE-based materials, while power electronics require thick copper layers. Common metallic finishes include:

● Hot Air Solder Leveling (HASL) (lead and lead-free options)

● Electroless Nickel Immersion Gold (ENIG) – Offers excellent conductivity and corrosion resistance.

● Immersion Silver – Provides a smooth surface for fine-pitch components.

● Organic Solderability Preservative (OSP) – A cost-effective, environmentally friendly option.

Creating the Stack-Up Sheet

Multi-layer PCBs require a stack-up sheet, which defines the arrangement of conductive and insulating layers. This helps in optimizing signal integrity and reducing electromagnetic interference.

Generating Manufacturing Data

After finalizing the design, the Gerber files, ODB+ files, or PDF drawings are created. These files contain information on trace layouts, drill locations, and layer specifications, enabling the fabrication process.

Transferring the Design to the Fabricator

Once the design files are ready, they are sent to Microchip USA for production. The process involves:

● Panelization & Phototooling: Preparing the PCB layout for mass production.

● Drilling & Routing: Creating vias and through-holes for component connections.

● Inspection & Testing: Ensuring compliance with design specifications using techniques such as golden board testing and netlist verification.

Introducing Microchip USA’s PCB Build Service

Microchip USA has created a hassle-free, efficient, and cost-effective PCB Build Service, tailored to engineers, PCB suppliers, and Electronics Manufacturing Services (EMS) providers.

How It Works

1. Submit Your Requirements: Provide details on the type of PCB, the quantity required, and your desired delivery timeframe, then upload your design files in Gerber, ODB+, or PDF formats.

2. Get a Quote: Microchip USA evaluates your request and provides a competitive quote, ensuring cost savings and faster lead times compared to traditional vendors.

3. Production & Delivery: Once approved, manufacturing begins, with guaranteed quality control and fast shipping options.

Comprehensive PCB Capabilities

Microchip USA supports a wide range of PCB technologies for various applications, so we can provide:

● Rigid PCBs – Standard and multi-layer designs.

● HDI (High-Density Interconnect) PCBs – Fine-pitch and compact designs.

● Heavy Copper PCBs – Supports high-power applications.

● High-Frequency PCBs – Optimized for RF and microwave applications.

● Flex & Rigid-Flex PCBs – Ideal for compact and wearable electronics.

● Laser Drill & Metal Core PCBs – Ensures precision and thermal management.

● Large Format & Ultra-Thin PCBs – Suitable for specialized applications.

Certifications & Quality Standards

Microchip USA’s PCB production adheres to the following industry-leading standards to ensure reliability and regulatory compliance:

● UL Certification – Safety compliance.

● ISO 9001:2015 – Quality management.

● ISO 13485:2016 – Medical device compliance.

● ISO 16949:2016 – Automotive industry standards.

● IECQ 0800:2017 – International electronic component certification.

Why Choose Microchip USA?

Microchip USA’s PCB Build Service is designed to provide unparalleled efficiency in the supply chain, by offering fast turnarounds, with standard delivery in 10 days — and expedited options for urgent orders. We also offer competitive pricing that can beat your current vendor’s prices to provide you with cost savings. Finally, we can handle orders of any size, from small prototype orders to large-scale production runs.

Requirements for Getting a Quote

To receive a quote, customers need to provide:

● Design files (Gerber, PDF, or ODB+).

● Quantity needed.

● Desired delivery timeframe.

Testing & Quality Assurance

Microchip USA employs a rigorous testing program for PCB reliability and functionality:

● Quick Return (3-5 Days) – Rapid turnaround for urgent projects.

● IPC-A-600 – Class 2 – Standard acceptance criteria.

● IPC-6012 – Class 3 – Higher reliability, extensive testing & documentation.

Why PCBs Matter More Than Ever

The PCB represents 8-12% of the cost Bill of Materials (BOM) for most electronic devices, which makes it a crucial aspect of electronics manufacturing. Each PCB is unique to the customer’s application, and pricing depends on delivery speed, quantity, and required technology. By offering a reliable, cost-effective PCB supply chain solution, Microchip USA helps businesses streamline production and increase profitability.

Our PCB Build Service is a game-changer for engineers and businesses seeking a reliable, efficient, and cost-effective solution for PCB manufacturing. With cutting-edge capabilities, robust quality assurance, and a customer-first approach, this service is set to redefine how PCBs are sourced and manufactured.

For more information or to request a quote, contact us today!