Lifecycle of an Electronic Component: From Design to Obsolescence

More from the Category

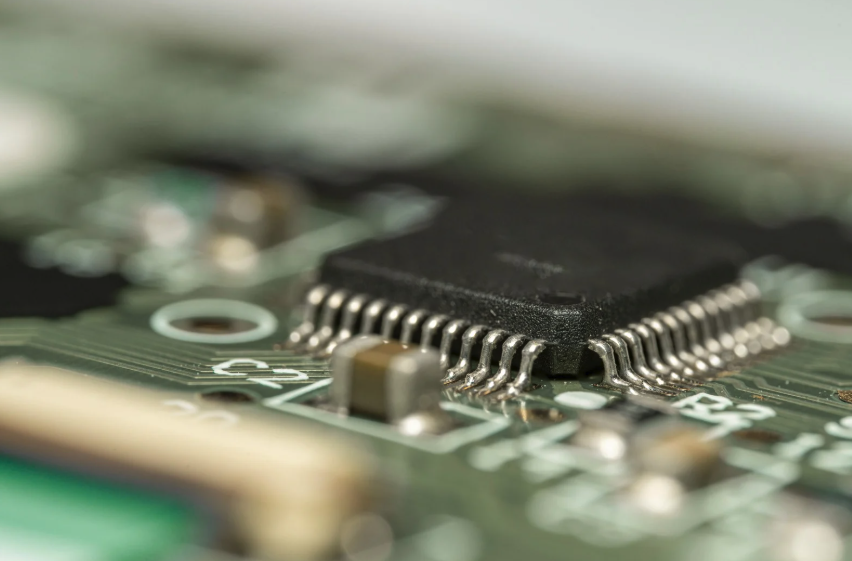

In the world of electronics, change is the only constant. The smartphone in your pocket, the server powering your favorite app, or the sensor in your car — each is built from components that were once cutting-edge but are now on a path to obsolescence. The lifecycle of electronic components is a relentless cycle of innovation, adoption, and eventual decline, shaped by the breakneck pace of technological advancement and shifting market demands.

Understanding this lifecycle is a strategic imperative for engineers and businesses. A single obsolete component can disrupt production lines, inflate costs, and delay time to market. Conversely, a well-managed lifecycle can unlock efficiencies, extend product longevity, and safeguard against supply chain shocks.

This article dives deep into the journey of an electronic component, from its inception in the design phase to its eventual retirement. We’ll explore the key stages of the electronic component life cycle, the challenges that arise at each step, and the strategies that can help engineers and businesses stay ahead of the curve. Whether you’re designing the next generation of IoT devices or managing a global supply chain, understanding the life cycle of electronic components is essential to navigating the complexities of modern electronics.

The Stages of the Electronic Component Life Cycle

The lifecycle of electronic components is a journey marked by innovation, adaptation, and eventual decline. Each stage — design, introduction, maturity, and obsolescence — presents unique challenges and opportunities.

Design and Development

Every electronic component begins as an idea, born from the need to solve a specific problem or enable a new technology. This phase is where engineers and designers collaborate to create components that meet performance, cost, and manufacturability requirements.

For example, the rise of 5G and IoT has driven demand for components that are faster, smaller, and more energy-efficient. This has led to innovations like advanced semiconductor materials, like gallium nitride, and novel packaging techniques, like 3D chip stacking.

However, the design phase is also fraught with challenges. Engineers must balance competing priorities, such as performance versus cost, while anticipating future market needs. A misstep here can lead to components that are either too expensive to produce or quickly rendered obsolete by newer technologies.

Introduction and Growth

Once a component is designed and tested, it enters the market. This is a critical phase, as early adoption can make or break its success. During this stage, manufacturers ramp up production, and the component begins to appear in a variety of applications.

Take, for instance, the introduction of USB-C connectors. Initially adopted by a handful of devices, USB-C quickly became the industry standard due to its versatility and performance. However, this phase also comes with risks, such as supply chain bottlenecks or quality control issues that can derail adoption.

Maturity

At the maturity stage, the component has reached peak adoption. It’s widely used, well-understood, and often considered a reliable choice for engineers. For example, DDR4 memory has been a mainstay in computing for years, offering a balance of performance and cost.

But maturity is a double-edged sword. As the market becomes saturated, competition intensifies, and profit margins shrink. Manufacturers may also face pressure to innovate, as newer technologies begin to emerge.

Decline and Obsolescence

Eventually, every component reaches the end of its lifecycle. Demand declines as newer, more advanced alternatives take its place. This is where obsolescence management becomes critical.

Consider the fate of through-hole components. Once ubiquitous, they’ve been largely replaced by surface-mount technology (SMT), which offers better performance and manufacturability. For engineers, this phase requires careful planning to avoid disruptions, whether through last-time buys, redesigns, or alternative sourcing.

Challenges in Managing the Life Cycle of Electronic Components

Navigating the lifecycle of electronic components is no small feat. Each stage brings its own set of challenges, from supply chain disruptions to the looming threat of obsolescence. For engineers and businesses, these challenges can have far-reaching implications, affecting everything from production timelines to bottom-line profitability.

Supply Chain Disruptions

The global supply chain is a complex web of suppliers, manufacturers, and distributors, and it’s highly vulnerable to disruptions. Geopolitical tensions, natural disasters, and even pandemics can wreak havoc on the availability of critical components.

The recent global chip shortage is a prime example. What began as a ripple effect from COVID-19 lockdowns quickly escalated into a full-blown crisis, impacting industries from automotive to consumer electronics. For engineers, this underscored the importance of diversifying suppliers and building resilient supply chains.

But supply chain challenges aren’t limited to external factors. Internal missteps, such as poor inventory management or over-reliance on a single supplier, can be just as damaging. The key is to anticipate risks and have contingency plans in place.

Obsolescence Management

Obsolescence is an inevitable part of the electronic component life cycle, but it doesn’t have to be a crisis. The real challenge lies in identifying and addressing obsolescence before it disrupts production.

End-of-life (EOL) notifications from manufacturers are a critical tool, but they’re often issued with little lead time. This leaves engineers scrambling to find alternatives or make last-time buys, which can be costly and inefficient.

Proactive obsolescence management is the solution. By monitoring lifecycle status and forecasting future trends, engineers can identify at-risk components early and take action. This might involve redesigning products, sourcing alternative components, or even collaborating with manufacturers to extend a component’s lifecycle.

Cost and Resource Allocation

Managing the lifecycle of electronic components is also a financial one. Every decision, from last-time buys to redesigns, comes with a price tag.

For example, stocking up on obsolete components might seem like a quick fix, but it ties up capital and increases inventory costs. On the other hand, redesigning a product to accommodate newer components can be expensive and time-consuming.

The key is to strike a balance. Tools like lifecycle management platforms can help by providing data-driven insights into cost-effective strategies. By optimizing decisions around inventory, sourcing, and redesigns, businesses can minimize costs while maximizing flexibility.

Strategic Implications for Engineers and Businesses

The challenges of managing the lifecycle of electronic components are significant, but they’re not insurmountable. With the right strategies, engineers and businesses can turn these challenges into opportunities, ensuring resilience, efficiency, and long-term success.

Proactive Lifecycle Management

Waiting for an end-of-life (EOL) notification is like waiting for a storm to hit to start preparations for inclement weather. Proactive lifecycle management is about staying ahead of the curve, anticipating changes, and taking action before they become problems.

One effective approach is to leverage lifecycle management tools and platforms. These solutions provide real-time data on component availability, lifecycle status, and market trends, enabling engineers to make informed decisions. There are multiple platforms that offer comprehensive databases and analytics to help identify at-risk components and plan accordingly.

Another key strategy is to establish a lifecycle management team or process within your organization. This team can monitor component lifecycles, assess risks, and develop contingency plans, ensuring that obsolescence doesn’t catch you off guard.

Design for Longevity

In the fast-paced world of electronics, designing for longevity might seem counterintuitive. But it’s a powerful way to mitigate the risks of obsolescence and extend the lifespan of your products.

One approach is to incorporate modularity into your designs. By using interchangeable components and standardized interfaces, you can easily upgrade or replace parts as needed, without redesigning the entire product. This not only reduces costs but also enhances flexibility and scalability.

Another strategy is to future-proof your designs by selecting components with longer lifecycles or broader applications. For instance, opting for widely adopted standards like USB-C or HDMI ensures compatibility and reduces the risk of obsolescence.

Collaboration Across the Supply Chain

No company is an island, especially in the electronics industry. Building strong relationships with suppliers, distributors, and manufacturers is essential for navigating the lifecycle of electronic components.

Transparency and communication are key. By sharing forecasts, demand projections, and lifecycle data with your partners, you can align your strategies and reduce the risk of disruptions. For example, some manufacturers offer lifecycle extension programs, where they continue producing a component for key customers even after it reaches EOL.

Collaboration also extends to the broader industry. Participating in industry groups, standards organizations, and forums can provide valuable insights into emerging trends and best practices. It’s a way to stay informed and connected in a rapidly evolving landscape.

Sourcing Parts in the Future

The lifecycle of electronic components is a journey defined by innovation, adaptation, and inevitable decline. From the drawing board to the recycling bin, each stage presents unique challenges and opportunities for engineers and businesses. In a world where technological advancements occur at breakneck speed, understanding and managing this lifecycle is a strategic imperative.

Supply chain disruptions, obsolescence risks, and cost pressures are real and ever-present. But with proactive lifecycle management, thoughtful design, and strong collaboration across the supply chain, these challenges can be transformed into opportunities. Tools and platforms that provide real-time data and insights are invaluable, enabling engineers to make informed decisions and stay ahead of the curve.

Ultimately, the lifecycle of electronic components is a reminder that change is the only constant in the electronics industry. By embracing this reality and adopting a forward-thinking approach, engineers and businesses can not only navigate the complexities of today but also build a foundation for success in the future.

In the end, it’s not just about managing components — it’s about managing change. And in a world that’s always evolving, that’s a skill worth mastering. Either that, or you should have a partner who already has that skill.

Microchip USA is the premier independent distributor of board-level electronics, and our team of experienced procurement specialists can help you manage your supply chain. We’re experts at supplying hard-to-find and obsolete parts with services tailored to simplify and optimize your supply chain. Contact us today!