The Future of Semiconductor Miniaturization

More from the Category

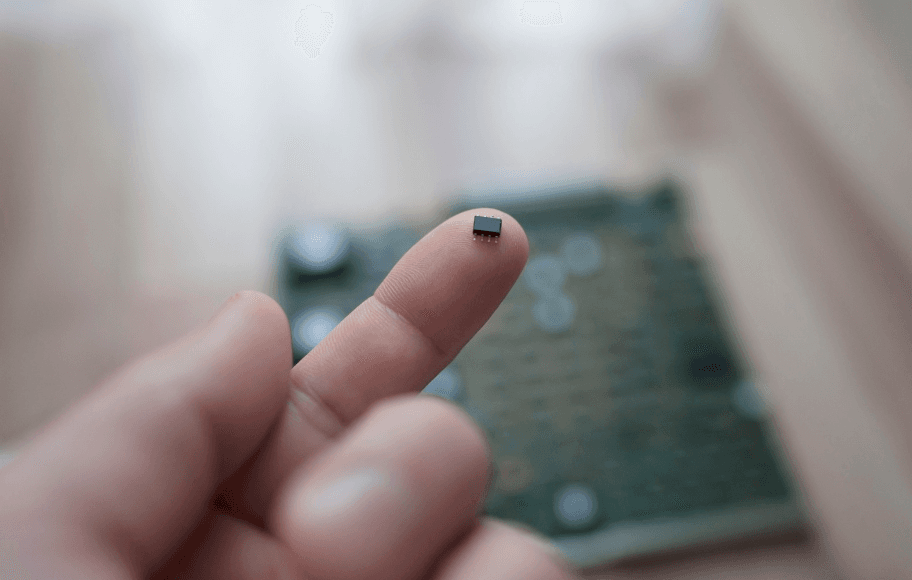

For decades, semiconductor miniaturization has been the driving force behind technological advancement. Smaller, faster, and more efficient transistors have powered everything from consumer electronics to data centers, and driven transformative innovations across industries. At the heart of this progress lies Moore’s Law, the guiding principle that has pushed engineers and scientists to double transistor density roughly every two years.

However, as transistors shrink into the single-digit nanometer range, the industry faces unprecedented challenges. Quantum effects, skyrocketing manufacturing costs, and the limits of current materials are reshaping the roadmap for chipmakers. The question is no longer just about how small we can go, but how we can sustain innovation without relying solely on traditional scaling.

This article explores the evolution of semiconductor miniaturization, the obstacles it faces, and the groundbreaking technologies poised to redefine the industry. For professionals navigating this dynamic field, understanding the next wave of solutions is essential for staying competitive in the race for technological supremacy.

The Evolution of Semiconductor Nodes

The story of semiconductor miniaturization is a tale of relentless innovation that is marked by milestone after milestone in the pursuit of smaller, more efficient technology. From the early days of micrometer-scale chips to today’s cutting-edge nanometer nodes, the semiconductor industry has continuously pushed the boundaries of what’s possible.

From Microns to Nanometers

The transition from micrometer to nanometer-scale processes revolutionized electronics and laid the foundation for modern computing and communication. Early chips measured transistor features in micrometers, but by the late 1990s, advancements in photolithography and materials science enabled the leap into nanometer-scale nodes. Each step brought improved transistor density, faster processing speeds, and reduced power consumption in order to meet the continuously growing demand for higher performance.

Key Milestones in Node Reduction

● 14nm Technology: Introduced by Intel in 2014, the 14nm node marked a breakthrough in efficiency and performance. It was among the first to widely use FinFET (Fin Field-Effect Transistor) technology, which improved energy efficiency by reducing leakage currents and increasing switching speed.

● 7nm Revolution: TSMC and Samsung led the charge with the introduction of 7nm nodes, which further refined FinFET designs. This node size became the foundation for high-performance computing (HPC) and AI workloads, and it is a staple for cutting-edge processors.

● 5nm and Beyond: Today, 5nm processes are mainstream and power flagship devices and AI accelerators. However, shrinking below 5nm has brought new hurdles, such as quantum tunneling effects and challenges in lithography. As we edge toward 3nm and 2nm nodes, innovations like Gate-All-Around (GAA) transistors and nanosheet technology are critical to maintaining the pace dictated by Moore’s Law.

The Limits of Traditional Scaling

While smaller nodes have historically meant better chips, the diminishing returns of node scaling are becoming clear. The physical constraints of silicon, along with the exponential rise in development costs, signal the end of "free" performance improvements from miniaturization alone. These challenges are pushing the industry to think beyond traditional planar scaling and explore new frontiers in chip design.

The evolution of semiconductor nodes reflects the industry's remarkable ingenuity, but as we approach the limits of Moore's Law, the focus is shifting toward new paradigms to sustain progress. The future of miniaturization lies in redefining not just the size of transistors but the entire architecture of chips themselves.

Challenges of Continued Miniaturization

As semiconductor nodes shrink, the challenges become increasingly complex because they blend the laws of physics with economic and technological constraints. These barriers demand new approaches to maintain the pace of innovation that the industry has grown accustomed to.

Physical Limitations

At the nanoscale, quantum effects become unavoidable. Phenomena like quantum tunneling cause electrons to "leak" through thin barriers, which increases power consumption and reduces reliability. These effects disrupt the performance of transistors and complicate scaling. Additionally, managing heat dissipation becomes critical, as smaller nodes lead to denser, hotter chips.

Material limits are another bottleneck. Silicon, the foundation of modern semiconductors, faces diminishing returns in conductivity and scaling. Alternative materials like graphene and carbon nanotubes hold promise, but their integration into mainstream manufacturing remains a challenge.

Economic and Manufacturing Constraints

The economic cost of miniaturization has skyrocketed. Developing a cutting-edge process node now requires billions of dollars in research and development, along with equally costly fabrication facilities. This high investment threshold limits participation to a small number of players, primarily TSMC, Samsung, and Intel.

Manufacturing precision is another significant hurdle. Creating transistors at the atomic scale demands extreme precision in lithography and material deposition. Tools like EUV lithography have enabled sub-5nm nodes but are costly and technically complex. Even slight imperfections can reduce yields, further driving up costs.

Design Complexity

Smaller nodes bring increased design complexity, as engineers must address issues like signal integrity, power distribution, and noise interference. Optimizing chip layouts at these scales requires advanced simulation tools and often extends development timelines.

Overcoming these challenges will require a mix of incremental improvements and disruptive innovations. As traditional scaling slows, the industry is pivoting toward new solutions that blend material science, architectural innovation, and advanced design techniques to keep Moore’s Law alive in spirit, if not in practice.

Innovative Approaches to Overcome Challenges

As semiconductor miniaturization faces its toughest challenges yet, the industry is pivoting to groundbreaking technologies and strategies to sustain progress. These approaches go beyond traditional scaling and explore new materials, architectures, and fabrication techniques to overcome the limitations of physics and economics.

Advanced Lithography Techniques

Lithography is the backbone of semiconductor manufacturing, and its evolution is critical to achieving smaller nodes. Extreme ultraviolet (EUV) lithography has been a game-changer that enables the precise patterning of features at sub-5nm scales. EUV uses shorter wavelengths of light to improve resolution and reduce multi-patterning steps, which streamlines production and increases yield.

Looking ahead, high-NA EUV (high numerical aperture) promises even greater precision by allowing manufacturers to push toward 2nm and beyond. These advancements will be instrumental in addressing quantum effects and maintaining transistor density.

Material Science Breakthroughs

Silicon's dominance is being challenged by the exploration of new materials that can better handle the demands of nanoscale devices:

● Graphene and Carbon Nanotubes: These materials offer superior electrical conductivity and thermal performance, so they are promising alternatives for next-generation transistors.

● Transition-Metal Dichalcogenides (TMDs): Ultra-thin materials like molybdenum disulfide (MoS₂) are being investigated for their ability to enable smaller, more efficient transistors.

● Advanced Interconnects and Dielectrics: Improving the materials used for interconnects and insulating layers can reduce resistance, enhance signal integrity, and improve chip reliability.

3D Integration and Packaging

As planar scaling becomes increasingly difficult, 3D integration offers a new dimension — literally. By stacking chips vertically, manufacturers can achieve higher densities without shrinking individual transistors.

● Chip Stacking: Techniques like through-silicon vias (TSVs) enable direct connections between stacked layers and improve performance while reducing power consumption.

● Heterogeneous Integration: Combining different types of chips (e.g., logic, memory, and sensors) into a single package enhances functionality and efficiency while bypassing the need for further node reductions.

These techniques are particularly effective in applications like high-performance computing and AI, where power and compute density are critical.

Chiplet Architectures

Instead of producing monolithic chips at smaller nodes, chiplet architectures break designs into smaller, modular components. These chiplets can be manufactured using different process nodes and then integrated into a single package using advanced interconnect technologies. This approach reduces manufacturing complexity and costs while maintaining performance scalability.

AI-Driven Semiconductor Design

Artificial intelligence (AI) is revolutionizing chip design. AI algorithms can optimize layouts, simulate performance, and identify potential issues far more efficiently than traditional methods. By leveraging AI, engineers can overcome design complexity and reduce time-to-market, especially for advanced nodes.

Neuromorphic and Quantum Computing

While traditional miniaturization is approaching its limits, alternative computing paradigms are emerging:

● Neuromorphic Computing: Mimicking the human brain’s architecture, this approach offers energy-efficient solutions for specific tasks like AI and pattern recognition.

● Quantum Computing: Though still in its infancy, quantum technology promises exponential improvements in processing power by leveraging quantum bits (qubits).

These paradigms are not direct replacements for traditional semiconductors, but they offer complementary solutions for tackling specific computational challenges.

Collaborative Ecosystems

Finally, collaboration across the semiconductor ecosystem is crucial. Foundries, equipment manufacturers, material scientists, and designers must work together to drive innovation. Initiatives like the European Chips Act and U.S. CHIPS Act are fostering partnerships to ensure the global semiconductor industry can tackle these challenges collectively.

By embracing these innovative approaches, the semiconductor industry is not only extending the era of miniaturization but also redefining the roadmap for future technologies. The fusion of cutting-edge science, engineering, and collaboration promises a bright future for the industry — even as it ventures into uncharted territory.

The Path Forward for Semiconductors

Semiconductor miniaturization has been the engine of technological progress for decades and enabled unprecedented advancements in computing, communication, and countless other fields. But as the industry approaches the physical and economic boundaries of traditional scaling, it faces an inflection point.

Innovative solutions like advanced lithography, new materials, 3D integration, and chiplet architectures are redefining what’s possible. At the same time, alternative paradigms such as neuromorphic and quantum computing offer complementary paths forward. The industry’s success will depend on its ability to embrace these innovations while fostering collaboration across the global ecosystem.

While the journey beyond 2nm may not follow the trajectory envisioned by Moore’s Law, the spirit of relentless innovation endures. The future of semiconductor miniaturization is no longer just about making things smaller — it’s about creating smarter, more efficient, and more sustainable technologies that will shape the next era of human progress.

Whether you need cutting edge semiconductor components like those discussed in this article, or you need obsolete parts for the systems you work on, Microchip USA is the perfect partner to supply them. Our staff of experienced procurement specialists has worked with clients in a variety of industries, and every component we supply is certified by industry leading quality control labs. Contact us today!