The Ultimate Guide to Capacitors: Everything You Need to Know

More from the Category

Capacitors are indispensable electronic components in circuits, designed to store and release electrical energy as needed. They serve a critical role across a broad spectrum of applications, from consumer electronics to power systems, thanks to their ability to manage energy flow, filter signals, and stabilize voltage. Their straightforward construction and availability in numerous shapes and sizes make them both practical and versatile for diverse use cases.

In modern electronic devices, capacitors are crucial for maintaining system stability and optimizing efficiency. They contribute to smooth power delivery, noise reduction, and improved circuit performance. A deeper understanding of their operation—centered around the electrostatic field generated between their conductive plates—enables engineers to design circuits with precision and reliability. Additionally, advancements in capacitor materials, such as ceramic and polymer dielectrics, have enhanced their durability, energy density, and performance in high-frequency and high-temperature environments.

How Capacitors Work

A capacitor is a fundamental component composed of two conductive plates separated by a non-conductive material called the dielectric. When voltage is applied, electric charges accumulate on the plates: one plate gains a positive charge, while the other acquires a negative charge. This separation of charges creates an electrostatic field between the plates, which is the mechanism by which the capacitor stores energy.

The capacity of a capacitor to store electrical energy is quantified as its capacitance, measured in farads (F). Capacitance depends on three key factors: the surface area of the plates (larger areas store more charge), the distance between the plates (closer plates increase capacitance), and the dielectric material’s properties (materials with higher permittivity enhance capacitance). One farad represents the ability to store one coulomb of charge at a potential difference of one volt.

The relationship between the charge stored and the voltage applied is proportional. When a voltage source is connected, current flows as the capacitor charges. Initially, the current is at its peak, but as the capacitor approaches its full charge, the current decreases until it ceases altogether. At this point, the voltage across the capacitor equals the applied voltage, and the capacitor maintains its charge.

Capacitors also exhibit dynamic behavior when the voltage changes. If the voltage across the plates increases or decreases, the capacitor either charges or discharges to match the new voltage. The time required for this adjustment is determined by the RC time constant, a product of the capacitor’s capacitance and the resistance of the circuit. This characteristic is critical for applications like voltage regulation, signal filtering, and power smoothing.

Modern capacitors are indispensable in electronic devices, ensuring stability and efficiency in circuits. They are widely used for energy storage, voltage smoothing, and coupling signals between different stages of electronic systems. Recent advancements in capacitor technology have introduced materials with higher energy densities, extended temperature ranges, and improved reliability, making them even more versatile for cutting-edge applications like renewable energy systems and electric vehicles.

By understanding the operating principles of capacitors, including the role of the electrostatic field and factors affecting capacitance, engineers can better design systems that optimize performance and reliability.

How Do Capacitors Work in Series Configurations?

Capacitors connected in series are commonly used to achieve higher voltage ratings than a single capacitor can handle alone. In a series configuration, the overall capacitance decreases, but the combined voltage rating increases. This makes series setups ideal for applications requiring high voltage capacity while maintaining compact designs.

Advantages of Using Series Configurations

• Increased Voltage Rating: A key benefit of series configurations is the ability to handle higher voltages. The total voltage rating of the setup is the sum of the individual capacitors' voltage ratings, enabling operation in high-voltage environments.

• Balanced Charge Distribution: In a series configuration, the same charge (Q) is distributed across all capacitors, ensuring balanced operation regardless of individual capacitance differences.

• Enhanced System Reliability: Using multiple capacitors in series can improve overall system reliability. If one capacitor fails (open circuit), the others can continue operating, albeit with a reduction in total capacitance.

Calculating Capacitance in Series

To determine the total capacitance (C_total) of capacitors in series, use the formula:

[ \frac{1}{C_{total}} = \frac{1}{C_1} + \frac{1}{C_2} + \frac{1}{C_3} + \ldots ]

This equation shows that the total capacitance is always less than the smallest individual capacitor in the series.

Example: If you have two capacitors, each rated at 10µF, the total capacitance would be:

[ \frac{1}{C_{total}} = \frac{1}{10µF} + \frac{1}{10µF} = \frac{1}{5µF} ]

Thus, ( C_{total} = 5µF )

Practical Applications

High-Voltage Power Supplies: Series capacitors are frequently used in high-voltage power supplies, ensuring the circuit can handle elevated voltage levels safely and efficiently.

Audio Equipment: In audio crossover networks, series capacitors help block low-frequency signals, protecting delicate high-frequency drivers from damage.

Signal Filtering: Series capacitors play a crucial role in signal processing, isolating specific frequency ranges in electronic circuits.

Pulse Circuits: Series configurations are often used in pulse circuits, where rapid charging and discharging are required for timing or control applications.

Key Considerations for Series Configurations

Voltage Balancing: To maintain even voltage distribution, capacitors in series should have identical values and characteristics. Using high-quality capacitors from trusted suppliers like Microchip USA helps ensure consistency.

Leakage Current: Leakage currents can differ between capacitors, causing imbalanced voltages in the series. Careful selection and testing of capacitors are essential to mitigate this issue.

Safety Margins: Always ensure that the voltage rating of the capacitors collectively exceeds the operating voltage of the circuit, allowing for safety margins against voltage surges.

Capacitors in series configurations offer significant advantages in high-voltage applications. With proper selection, design, and attention to balancing considerations, they enhance performance, reliability, and efficiency across various electronic systems. Recent advancements in capacitor materials and manufacturing have further improved their capability to handle high-stress environments, making them indispensable in modern electronics.

Understanding Impedance and Reactance in Capacitors

When working with capacitors, two essential concepts frequently arise: impedance and reactance. These properties govern how capacitors interact with alternating current (AC) circuits, influencing their performance in various applications.

Reactance

Reactance refers to the opposition a capacitor presents to AC flow. For capacitors, this is specifically called capacitive reactance (Xc) and is measured in ohms (Ω). Capacitive reactance is frequency-dependent and decreases as the AC frequency increases. This relationship is mathematically expressed as:

Xc=12πfCX_c = \frac{1}{2 \pi f C}Xc =2πfC1

Where:

XcX_cXc : Capacitive reactance (Ω)

fff: Frequency of AC (Hz)

CCC: Capacitance (F)

This formula highlights that capacitors allow higher-frequency signals to pass more easily, making them integral to applications like signal filtering and AC coupling.

Impedance

Impedance (ZZZ) is a comprehensive measure that combines resistance (RRR) and reactance (XXX) into a single value, encompassing all forms of opposition to current flow in a circuit.

• In a purely capacitive circuit, impedance equals capacitive reactance: Z=XcZ = X_cZ=Xc

• In circuits with both resistance and reactance, impedance is calculated using the phasor sum: Z=R2+Xc2Z = \sqrt{R^2 + X_c^2}Z=R2+Xc2

Impedance is critical for analyzing AC circuits as it dictates how effectively a capacitor operates under specific conditions.

Key Takeaways

Capacitive Reactance: Governs how easily AC flows through a capacitor, inversely related to the AC frequency.

Impedance: A broader measure that accounts for all opposition to current, essential for designing and troubleshooting AC circuits.

Understanding these concepts enables precise predictions of a capacitor’s behavior in complex AC systems, ensuring effective design and efficient operation.

Breakdown Voltage in Capacitors

The breakdown voltage of a capacitor is the maximum electric field strength that its dielectric material can withstand before failing. Exceeding this limit causes the dielectric to become conductive, leading to catastrophic failure in the form of a short circuit.

Critical Factors of Breakdown Voltage

Electric Field Intensity: The electric field strength within the capacitor increases with voltage. Once this field exceeds the dielectric's threshold, breakdown occurs.

Dielectric Material: The insulating material between the capacitor’s plates determines the breakdown voltage. High-quality dielectrics like ceramic, polymer, or tantalum can significantly improve a capacitor's voltage-handling capabilities.

Failure Point: The breakdown voltage is the threshold at which the dielectric fails, allowing current to pass through. This marks the operational limit of the capacitor.

Key Points to Consider

Operational Safety: Always select capacitors with a breakdown voltage comfortably higher than the maximum expected operating voltage to ensure reliability.

Material Selection: Advanced dielectric materials can enhance breakdown voltage and improve capacitor performance in demanding environments.

Applications: High-breakdown-voltage capacitors are essential in high-power circuits, surge protectors, and power transmission systems.

By understanding and respecting the breakdown voltage, engineers can design systems that maximize capacitor longevity and prevent premature failures. Combined with impedance and reactance knowledge, these principles form the foundation for using capacitors effectively in modern electronics.

Understanding the Q Factor of a Capacitor

The Q factor, or Quality factor, is a vital parameter for evaluating a capacitor’s efficiency in AC circuits. It represents the ratio of a capacitor’s reactance to its equivalent series resistance (ESR), providing insight into how effectively the capacitor performs with minimal energy loss.

Key Concepts

Capacitance: The ability of a capacitor to store and release electrical charge.

Dielectric Materials: Insulating materials between the capacitor plates that influence capacitance and Q factor.

Reactance and Impedance: The capacitor’s resistance to changes in current flow, critical for understanding AC behavior.

Parasitic Inductance: Unintended inductance in a capacitor, which can lower the Q factor at higher frequencies.

Calculating the Q Factor

The Q factor of a capacitor can be determined using the following steps:

Determine Reactance (XcX_cXc ):

Xc=12πfCX_c = \frac{1}{2\pi f C}Xc =2πfC1

Where:

XcX_cXc: Capacitive reactance (Ω)

fff: Frequency of the AC signal (Hz)

CCC: Capacitance (F)

Identify Equivalent Series Resistance (ESR): The ESR is typically provided in the capacitor’s datasheet and represents the real-world losses in the capacitor.

Compute Q Factor:

Q=XcESRQ = \frac{X_c}{ESR}Q=ESRXc

The higher the Q factor, the more efficient the capacitor, with less energy dissipated as heat.

Importance of the Q Factor

Signal Integrity: A high Q factor ensures better signal fidelity, making it essential in filtering and tuning circuits.

Energy Efficiency: Capacitors with higher Q factors experience minimal energy loss, which is particularly important in resonant circuits and high-frequency applications.

Performance Indicator: The Q factor serves as a benchmark for a capacitor’s overall performance under AC conditions, especially in demanding environments.

Practical Considerations

Frequency Dependence: The Q factor varies with frequency, so it must be evaluated at the operating frequency of your application.

Material Selection: Low-loss dielectric materials, such as polypropylene or ceramic, contribute to higher Q factors.

Parasitic Elements: Minimizing parasitic inductance and resistance is critical, especially in high-frequency circuits, to maintain a high Q factor.

Thermal Stability: ESR and Q factor can fluctuate with temperature. Select capacitors with stable characteristics across your circuit’s operating temperature range.

The Q factor is a cornerstone of capacitor performance in AC circuits, directly impacting efficiency, signal clarity, and energy conservation. By understanding and optimizing this parameter—through careful component selection and circuit design—you can ensure enhanced performance, reduced losses, and longer-lasting electronic systems in both everyday and advanced applications.

Understanding Parasitic Inductance and Resistance in Capacitors

In an ideal scenario, capacitors would function purely based on their capacitance. However, real-world capacitors exhibit imperfections, such as parasitic inductance and resistance, which can impact their performance, particularly in high-frequency applications.

What is Parasitic Inductance?

Parasitic inductance refers to the unintended inductive effects within a capacitor caused by its physical construction. Key contributors to parasitic inductance include:

Conductors and Lead Wires: The wires and connections used to connect the capacitor to a circuit generate small magnetic fields as current flows through them.

Internal Connections: The design and materials inside the capacitor also contribute to inductance.

These inductive effects become increasingly significant at high frequencies, where they can interfere with the capacitor’s intended function by shifting its impedance and altering its behavior in the circuit.

What is Parasitic Resistance?

Parasitic resistance is the unintended resistive property of a capacitor, caused by:

Conductive Materials: The leads, plates, and internal connections introduce resistance.

Dielectric Material: Some dielectric materials have inherent resistive properties that add to the overall parasitic resistance.

This resistance causes energy losses as heat, which can reduce the capacitor’s efficiency and accuracy. In applications like high-frequency circuits or precision signal processing, even small resistances can lead to noticeable performance degradation.

Key Points to Remember

Construction Elements: Lead wires, internal connections, and the choice of dielectric material are primary contributors to parasitic inductance and resistance.

High-Frequency Impact: Parasitic inductance and resistance become more pronounced at higher frequencies, potentially degrading the capacitor’s performance. They can cause signal distortion, energy loss, or unwanted resonances in circuits.

Energy Dissipation: Parasitic resistance leads to heat generation, which can reduce the efficiency of a capacitor and, in extreme cases, affect the reliability and lifespan of the circuit.

Minimizing Parasitic Effects

Low-Inductance Design: Use capacitors with short leads, tight internal connections, or surface-mount technology (SMT) to minimize parasitic inductance.

High-Quality Dielectrics: Select capacitors with low-loss dielectric materials to reduce resistive losses.

Frequency-Optimized Components: For high-frequency applications, choose capacitors specifically designed to operate efficiently at your circuit’s frequency range.

Circuit Design: Include compensatory components, such as series resistors or ferrite beads, to mitigate the effects of parasitics.

Understanding and addressing parasitic inductance and resistance are essential for designing high-efficiency and reliable electronic systems. These factors, though small in magnitude, can significantly influence capacitor behavior, particularly in high-speed, precision, or high-frequency circuits. By carefully selecting components and optimizing circuit designs, engineers can minimize parasitic effects and enhance overall system performance.

Material Choice and Configuration in Capacitors

While all capacitors operate on the same basic principle of storing energy through an electric field, the choice of materials and configuration can vary significantly. These differences are critical in determining a capacitor’s performance characteristics and suitability for specific applications. The dielectric material and the plate configuration directly impact key factors such as capacitance, voltage rating, and tolerance.

Dielectric Material

The dielectric material, the insulating layer between the capacitor plates, is one of the most important determinants of a capacitor’s properties. Common dielectric materials and their characteristics include:

Ceramic: High dielectric constant allows compact designs with high capacitance. Ideal for general-purpose, high-frequency, and temperature-stable applications.

Electrolytic: Provide high capacitance per unit volume, making them suitable for energy storage and filtering. They are polarized and must be used with fixed polarity in circuits.

Film: Features low ESR and excellent long-term stability. Commonly used in high-precision and power applications.

Tantalum: Offer high reliability and good performance in compact packages. Often found in portable devices and sensitive circuits.

Polymer: Deliver high capacitance with low ESR for excellent high-frequency performance. Ideal for energy storage and decoupling in modern electronics.

Plate Configuration

The configuration of the plates also plays a significant role in determining the capacitor’s behavior:

Parallel Plate: Standard design for most capacitors, offering a predictable capacitance value based on plate area and separation.

Multilayer: Found in multilayer ceramic capacitors (MLCCs), these provide higher capacitance in a compact size by stacking multiple plate-dielectric layers.

Wound Foil: Used in electrolytic and film capacitors, where plates are wound into a cylindrical shape to save space.

Interdigitated: Common in specialized applications, this configuration increases surface area to achieve higher capacitance values in compact spaces.

Performance Factors Influenced by Material and Configuration

Capacitance: Determined by the dielectric constant of the material and the effective surface area of the plates.

Voltage Rating: The breakdown voltage depends heavily on the dielectric material’s properties and the distance between the plates.

Tolerance: High-precision applications require materials and configurations that minimize variations in capacitance.

Temperature and Frequency Stability: The dielectric material and plate design dictate how well a capacitor performs across varying temperatures and frequencies.

Applications

High-Frequency Circuits: Ceramic and polymer capacitors excel due to their low ESR and excellent stability.

Energy Storage: Electrolytic and tantalum capacitors are ideal for providing high capacitance in compact sizes.

Signal Filtering: Film and ceramic capacitors are commonly used for their precision and stability.

By carefully selecting the dielectric material and optimizing the plate configuration, designers can tailor capacitors to meet the specific demands of modern electronic systems. These decisions not only affect performance but also play a crucial role in ensuring reliability and efficiency in applications ranging from consumer electronics to industrial systems.

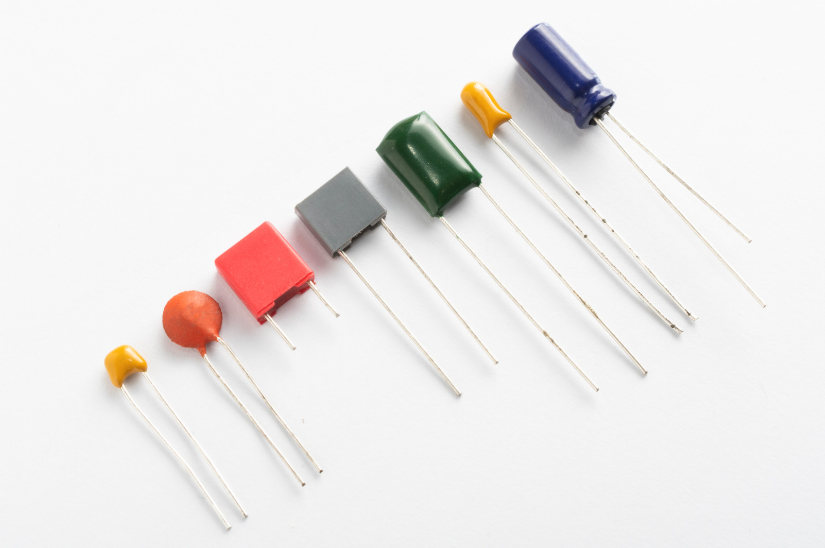

Types of Capacitors

Capacitors come in a variety of types, each with unique properties suited for specific applications. Understanding these differences is crucial for selecting the right capacitor to meet performance requirements in electronic circuits. Below are the most common types of capacitors and their characteristics.

Ceramic Capacitors

Ceramic capacitors are the most widely used type because of their affordability, versatility, and availability in multiple shapes and sizes. They use a ceramic material as the dielectric, which provides a high dielectric constant. These capacitors are non-polarized, meaning they can be connected in either direction, making them suitable for a broad range of applications. They are ideal for high-frequency applications such as filtering, tuning, and decoupling. Ceramic capacitors offer high capacitance per unit volume at a low cost and are available in small sizes. However, they have lower tolerance compared to other types and are classified into different classes: Class 1 for high stability and Class 2 for higher capacitance with reduced stability.

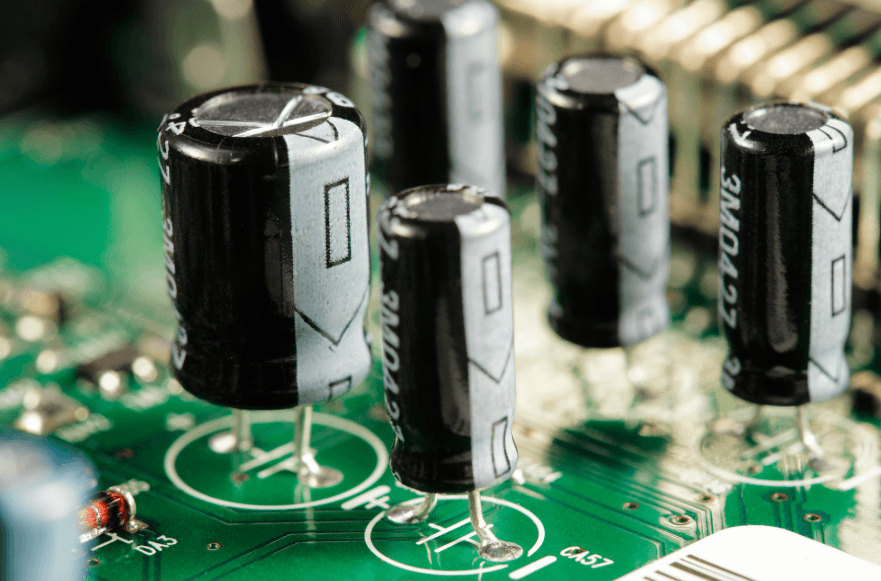

Electrolytic Capacitors

Electrolytic capacitors are polarized, which means they have specific positive and negative terminals and must be connected with the correct polarity. They are widely used in applications that require high capacitance values, such as power supplies and audio amplifiers. These capacitors use an electrolyte, which may be liquid or solid, as the dielectric material. Electrolytic capacitors are suitable for low-frequency applications, particularly for smoothing voltage fluctuations. Their primary advantage lies in providing high capacitance in a compact form. However, they are sensitive to temperature and frequency, making them less effective in high-frequency circuits. They also exhibit higher tolerance than ceramic capacitors and are prone to leakage current and parasitic inductance.

Tantalum Capacitors

Tantalum capacitors are similar to electrolytic capacitors but offer a higher capacitance per unit volume, making them ideal for compact electronic devices. These capacitors use tantalum oxide as the dielectric and are polarized, requiring correct polarity to avoid damage. They are commonly found in portable electronics such as smartphones and wearables. Tantalum capacitors are highly reliable and deliver high capacitance in small packages. However, they are sensitive to overvoltage, which can lead to failure.

Film Capacitors

Film capacitors use a thin film of metal or metalized plastic as the dielectric, which ensures excellent performance in applications requiring precision and low distortion. These capacitors are non-polarized, making them suitable for both AC and DC circuits. They are often used in high-performance audio and video equipment and in signal filtering. Film capacitors are valued for their high accuracy, stability over time, low distortion, and low equivalent series resistance (ESR). The main limitation is their relatively lower capacitance per unit volume compared to ceramic and electrolytic capacitors.

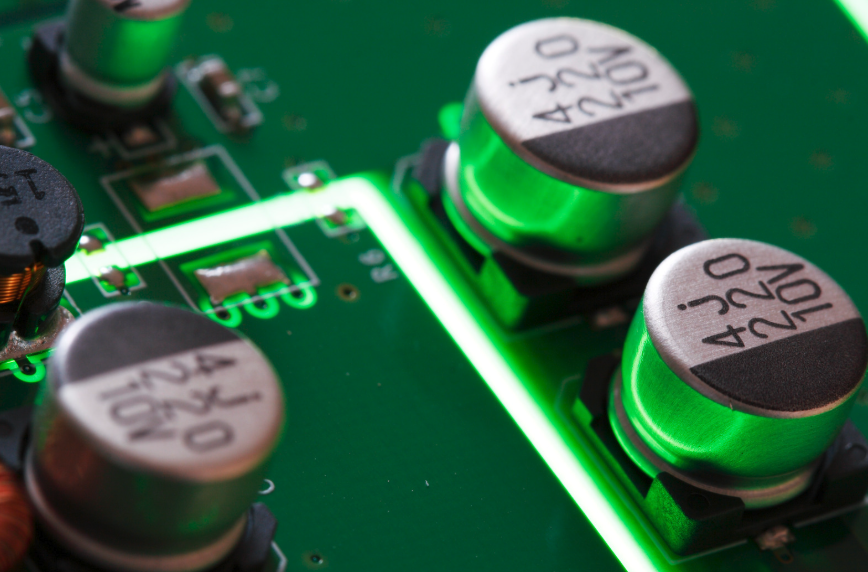

Polymer Capacitors

Polymer capacitors represent a specialized category that uses a solid conductive polymer as the electrolyte instead of a liquid or gel. This design improves reliability, performance, and efficiency, making them a preferred choice in modern electronics. These capacitors exhibit low equivalent series resistance (ESR), which reduces power losses and improves filtering efficiency in power supply circuits, making them ideal for high-speed and high-efficiency applications. Polymer capacitors are highly resistant to drying out and can withstand harsh environmental conditions, resulting in a longer operational lifespan with minimal degradation. They offer high capacitance and wide voltage ratings, making them suitable for consumer electronics, industrial systems, and automotive applications. Polymer capacitors also have minimal parasitic inductance and resistance, making them ideal for RF circuits, power delivery networks, and high-speed data systems. They tolerate high voltages before dielectric failure and have low leakage current, making them highly reliable in demanding applications such as power converters and automotive electronics. Their applications include smartphones, laptops, gaming consoles, power management systems, electric vehicles, industrial automation, aerospace systems, and high-speed computing environments like servers and data centers. With their ability to handle high frequencies and voltages, polymer capacitors are integral to next-generation electronic design.

Supercapacitors

Supercapacitors, also known as ultracapacitors or double-layer capacitors, are designed for high power density and energy storage. They use activated carbon as the dielectric material, which provides a high surface area for charge storage. Supercapacitors are commonly used in electric vehicles, renewable energy systems, and backup power supplies. They offer high energy storage capacity compared to conventional capacitors, a long operational lifespan, and the ability to charge and discharge quickly. However, their limitations include lower voltage ratings and lower capacitance per unit volume relative to other capacitor types.

Trimmer Capacitors

Trimmer capacitors are small, adjustable capacitors designed for fine-tuning circuits where precise capacitance adjustment is required. Unlike fixed capacitors, trimmers can be manually adjusted to achieve optimal circuit performance, making them essential in calibration-dependent applications such as RF tuning, oscillators, and sensor circuits. They allow fine-tuning of circuit parameters within a specific range and come in compact sizes suitable for space-constrained designs. These capacitors typically provide capacitance values from a few picofarads to a few nanofarads, making them suitable for high-frequency applications. They are built from stable materials such as ceramic, mica, or plastic and are available in both surface-mount and through-hole configurations. Trimmer capacitors are widely used in RF circuits, oscillators, audio and video tuning circuits, capacitive sensors, and medical equipment. Their primary advantage is precision and adjustability, though they have a limited capacitance range and require manual tuning, which can be a drawback in automated systems.

Filter Capacitors

Filter capacitors are essential components in electronic circuits, designed to reduce unwanted noise and smooth out voltage fluctuations. By stabilizing power and minimizing interference, they enhance performance and prolong the life of electronic devices. Filter capacitors play a key role in noise reduction by suppressing high-frequency noise and preventing unwanted signals from disrupting circuit operation. They also maintain a stable voltage level by filtering out ripples in power supplies, ensuring consistent DC voltage for connected components, which prevents malfunctions and extends the lifespan of sensitive electronics.

In power supplies, when AC voltage is rectified into DC, residual fluctuations remain. Filter capacitors store and release charge as needed, converting pulsating DC into a smoother, more stable output. Without them, power inefficiencies could lead to overheating and erratic performance. In audio circuits, they eliminate hums and background noise, improving clarity. In communication systems, they filter interference to ensure clearer and more reliable signal transmission.

Filter capacitors come in different types for different applications. Electrolytic capacitors offer high capacitance values and are widely used in power supply filtering due to their ability to handle higher voltages and currents. Ceramic capacitors, though offering lower capacitance, provide excellent high-frequency performance and low ESR, making them efficient for signal processing and high-speed applications. Film capacitors provide stable and reliable performance over time, making them suitable for precision filtering in high-fidelity audio systems and power electronics.

Their real-world applications include power supply units for computers, industrial machines, and consumer electronics to prevent voltage fluctuations, audio equipment to ensure clear and crisp sound quality, communication devices to enhance signal clarity, and automotive electronics for voltage stabilization and electromagnetic interference reduction. Filter capacitors are indispensable in modern electronics, ensuring reliable operation across a wide range of systems.

General Capacitor Considerations

Energy Storage: Capacitors store energy in an electrostatic field, with capacitance (CCC) defined as the ratio of stored charge (QQQ) to the applied voltage (VVV):

C=QVC = \frac{Q}{V}C=VQ

Parasitic Effects: Real-world capacitors exhibit parasitic inductance and resistance, which can affect their performance, especially at high frequencies.

Breakdown Voltage: Every capacitor has a maximum voltage it can handle before its dielectric material fails, leading to potential circuit damage.

By understanding the strengths, limitations, and applications of each capacitor type, engineers can make informed decisions to optimize circuit performance and ensure reliability across various electronic systems.

Applications of Capacitors

Capacitors are integral to a vast range of electronic applications, from basic circuits to advanced industrial and automotive systems. Their ability to store and release electrical energy, filter signals, and stabilize voltage makes them indispensable in modern technology.

Power Management and Regulation

Power Supplies: Capacitors play a crucial role in power supply circuits by filtering noise and stabilizing voltage levels. Capacitors also store excess energy and discharge it when needed, ensuring a consistent DC output for electronic devices.

In switch-mode power supplies (SMPS) and linear regulators, capacitors smooth out ripples, improving efficiency and performance.

Energy Storage in Backup Systems: Large-capacity supercapacitors (ultracapacitors) are used in uninterruptible power supplies (UPS), emergency lighting, hybrid energy storage systems.

These capacitors deliver rapid bursts of energy, preventing power interruptions.

Signal Processing and Audio Applications

Audio Equipment: In audio equipment, capacitors filter noise and separate audio frequencies in speaker crossover networks. Capacitors also enable tone control circuits for adjusting bass, midrange, and treble.

Radio Frequency (RF) Circuits: In RF communication systems, capacitors filter and tune frequencies for transmitters, antennas, and signal processing. They also ensure stable communication and reduce interference.

Timing and Oscillation

Timing Circuits: Capacitors, combined with resistors, are fundamental in oscillators, pulse generators and frequency synthesizers. They control charge/discharge rates to produce precise signals for microcontrollers, digital clocks, and signal generators.

Oscillators and Waveform Generators: Capacitors in LC and RC oscillators generate waveforms for signal processing, FM modulation, and function generators. They also store and release energy at specific intervals for stable frequency output.

Motor and Lighting Applications

Motor Starters and Power Factor Correction: In single-phase induction motors, capacitors provide starting torque and improve power factor in AC circuits, reducing reactive power losses and enhancing efficiency.

Lighting Systems: In lighting systems, capacitors improve performance of fluorescent lamps, LED drivers, and HID lighting. Capacitors also reduce flickering and compensate for reactive power, lowering energy consumption.

Computers and High-Speed Electronics

Power Stabilization in Computer Systems: Capacitors stabilize voltage in motherboards, graphics cards and RAM modules. Polymer capacitors with low ESR are critical in high-performance computing (HPC) and gaming systems.

Data Storage and Memory Backup: Certain capacitors support non-volatile memory (NVM) backup for flash memory and SRAM, retaining data during power loss.

Automotive, Aerospace, and Defense Applications

Automotive Systems: Capacitors are key in engine ignition systems, electronic control units (ECUs), battery management systems (BMS) and electric vehicle (EV) power electronics. They filter noise, stabilize voltage, and provide energy bursts for ignition and regenerative braking.

Aerospace and Military Electronics: Capacitors in radar, satellite, and avionics must withstand high radiation, extreme temperatures and vibration. Tantalum and ceramic capacitors are preferred for reliability and stability.

Renewable Energy and Power Conditioning

Solar and Wind Energy Systems: Capacitors regulate energy in solar inverters and wind turbine generators. Film capacitors are favored for their long lifespan and efficiency.

Grid Stabilization: Capacitors correct power factors, reduce transmission losses and stabilize frequency variations in electrical grids.

Advanced Circuit Applications: Coupling and Decoupling

Coupling Capacitors

Transmit AC signals while blocking DC bias:

Signal Transmission: Clean AC transfer between stages.

Impedance Matching: Ensures maximum power transfer.

Noise Reduction: Blocks DC to reduce interference.

Decoupling Capacitors

Help filter high-frequency noise and provide local energy storage, stabilizing voltage supplies for sensitive integrated circuits (ICs).

Noise Filtering: Decoupling capacitors are deployed to filter out high-frequency noise from power supply lines, ensuring a stable DC supply to critical components.

Voltage Stabilization: These capacitors act as local energy reservoirs, providing instantaneous current to ICs (integrated circuits) and other active components during transient conditions, thereby stabilizing the voltage levels.

Minimizing Crosstalk: In digital circuits, decoupling capacitors help minimize crosstalk by isolating different parts of the circuit and preventing unwanted interactions between high-speed signal lines.

Choosing the Right Capacitor

Capacitance Value: Match signal frequency and noise requirements.

Voltage Rating: Ensure adequate voltage tolerance.

ESR (Equivalent Series Resistance): Prefer low ESR for decoupling.

Parallel Capacitor Configurations

A parallel capacitor configuration is when two or more capacitors are connected so that their corresponding terminals share the same two nodes, resulting in the same voltage across each capacitor. In this setup, the total capacitance is the sum of all individual capacitances, increasing the circuit’s overall energy storage capacity.

Benefits

The benefits of a parallel capacitors configuration are increased capacitance for improved charge storage, uniform voltage distribution and load balancing to reduce stress on components.

Applications

• Power Supply Smoothing: Reduces voltage fluctuations

• Signal Filtering: Enhances audio and communication performance

• Energy Storage: Improves renewable energy system efficiency

How Capacitors Store Energy

Capacitors store energy in an electrostatic field between two conductive plates separated by a dielectric material. When voltage is applied:

• Charge Accumulation: One plate stores positive charge while the other accumulates negative charge.

• Electrostatic Field Formation: The energy is stored in the form of an electric field across the dielectric.

• Discharge Cycle: When needed, the stored energy is released back into the circuit, enabling rapid power bursts.

Capacitors are one of the most versatile and essential components in electronics. Their ability to store energy, regulate voltage, filter noise, and improve efficiency makes them indispensable across power systems, communication networks, computing, automotive, aerospace, and renewable energy applications. By understanding capacitor functionalities and selecting the right type, engineers can design highly efficient and reliable electronic systems for modern and future technologies.

Troubleshooting Capacitors

Capacitors play a crucial role in electronic circuits, but they can fail due to overvoltage, excessive temperature, aging, or manufacturing defects. A faulty capacitor can lead to circuit malfunctions, reduced performance, or even damage to other components. Understanding how to identify, test, and prevent capacitor failures is essential for maintaining circuit reliability.

Common Causes of Capacitor Failures

Overvoltage: Exceeding the capacitor’s voltage rating can cause dielectric breakdown, leading to failure.

Temperature Stress: Exposure to high temperatures accelerates degradation, especially in electrolytic capacitors.

Aging and Degradation: Over time, capacitors lose their effectiveness due to material breakdown and chemical aging.

Incorrect Installation: Improper polarization or voltage mismatches can lead to circuit malfunctions.

Parasitic Effects: Resistance and inductance in the capacitor’s leads can impact performance in high-frequency applications.

Troubleshooting Techniques

Visual Inspection: A quick, non-invasive check can reveal common capacitor failures. Look for:

• Bulging or swelling: Indicates gas buildup due to dielectric breakdown.

• Leaking electrolyte: Suggests internal failure in electrolytic capacitors.

• Burn marks or discoloration: Signs of overheating or electrical stress.

Solution: If any of these signs are present, replace the capacitor immediately.

Capacitance Measurement: A capacitor’s capacitance should remain close to its rated value. Use a capacitance meter to measure it.

• If capacitance is significantly lower than the rated value, the capacitor has likely degraded.

• A completely open circuit reading indicates a capacitor failure.

Solution: Replace capacitors with significantly reduced capacitance.

ESR (Equivalent Series Resistance) Measurement: High ESR can cause inefficient capacitor performance, especially in power filtering and audio applications. Use an ESR meter to test:

• A capacitor with significantly higher ESR than its rated value is failing.

Solution: Replace capacitors with excessive ESR to restore performance.

Circuit Analysis: If a circuit is malfunctioning:

• Check voltage fluctuations: Unstable voltage could indicate capacitor failure.

• Observe power supply noise: Excessive noise suggests filtering capacitors are not functioning correctly.

• Swap suspected capacitors with new ones and retest the circuit.

Solution: If replacing a capacitor restores normal function, the original component was faulty.

Preventing Capacitor Failures

Managing Aging and Degradation: Electrolytic capacitors typically degrade over time, especially if exposed to high temperatures or voltage fluctuations.

• Expected Lifespan: Electrolytic capacitors should be replaced every 10-15 years in critical systems, even if they appear functional.

• Humidity and Environment: High moisture levels can accelerate degradation.

Solution: Regularly replace old capacitors in aging equipment.

Selecting the Right Voltage Rating: Using a capacitor with an inadequate voltage rating can result in overvoltage stress and premature failure.

• Choose capacitors with a voltage rating at least 20-50% higher than the expected circuit voltage.

Solution: Always check and match capacitor voltage ratings with circuit requirements.

Monitoring Temperature Conditions: Capacitors have maximum temperature ratings, exceeding them can lead to early failure.

• High-power circuits generate heat that can degrade capacitors over time.

• Electrolytic capacitors dry out faster when exposed to excessive heat.

Solution: Ensure adequate cooling and use high-temperature-rated capacitors when necessary.

Correct Polarization: Incorrect polarity in electrolytic capacitors can cause catastrophic failure, including explosions or leakage.

• Check capacitor polarity before installation—the longer lead is typically the positive terminal.

• For polarized capacitors, double-check markings on PCBs before soldering.

Solution: Always confirm the correct orientation of capacitors in circuits.

Controlling Leakage Current: Leakage current is the small current that flows through a capacitor’s dielectric, even when it’s not supposed to.

• Excessive leakage current leads to self-heating, reducing capacitor lifespan.

• High leakage in low-power circuits can drain charge, affecting performance

Solution: Regularly test leakage current to prevent premature failure.

Understanding Capacitor Limitations

While capacitors are designed for efficiency, real-world factors affect their performance.

Parasitic Inductance and Resistance

• Issue: The leads and materials introduce unwanted resistance and inductance, especially at high frequencies.

• Impact: This can distort signals in RF and high-speed circuits.

Solution: Use low-ESR capacitors and ensure proper PCB layout to minimize interference.

Breakdown Voltage

• Issue: Each capacitor has a maximum dielectric strength—exceeding this voltage causes failure.

• Impact: Breakdown leads to short circuits or permanent damage.

Solution: Always use capacitors rated above expected voltages to prevent failure.

Leakage Current Effects

• Issue: High leakage current reduces charge retention and can lead to overheating.

• Impact: This can shorten capacitor lifespan and reduce circuit efficiency.

Solution: Regularly check leakage current values to prevent failures in low-power and precision circuits.

Frequently Asked Questions (FAQs)

What happens when a capacitor fails?

A failed capacitor can lead to power supply instability, excessive noise in circuits, malfunctioning oscillators and filters, as well as overheating that may damage nearby components.

How can I tell if a capacitor is faulty without special equipment?

You can check for visible signs of damage such as bulging, leaking, or discoloration. If you are unsure, replacing the capacitor and testing the circuit for improvements is a practical approach.

What causes capacitors to leak electrolyte?

Electrolyte leakage can occur due to overheating from excessive current or poor ventilation, manufacturing defects in the dielectric material, or overvoltage stress that exceeds the capacitor’s rated limits.

What is the difference between ESR and capacitance failure?

When a capacitor fails due to low capacitance, it no longer stores charge effectively. In contrast, a failure caused by high Equivalent Series Resistance (ESR) means the capacitor introduces excessive resistance, reducing its efficiency.

How often should capacitors be replaced?

Electrolytic capacitors typically need replacement every 10 to 15 years in critical applications, while film and ceramic capacitors can last for decades unless they are physically damaged.

Troubleshooting capacitors is essential for maintaining circuit efficiency, stability, and longevity. Regular visual inspections, capacitance measurements, and ESR testing can help identify failing capacitors before they cause significant issues. By selecting the right capacitor types, ensuring proper installation, and monitoring real-world operating conditions, engineers can prevent common capacitor failures and enhance the reliability of electronic systems.

Small Component, Big Impact

Capacitors are essential electronic components used in a wide range of applications. From power supplies and audio systems to cutting-edge industrial and automotive applications, these components are fundamental to circuit performance and reliability. Understanding their functionality, types, and real-world applications empowers you to design, troubleshoot, and optimize electronic circuits with confidence.

As technology advances, capacitors will continue to drive innovation, enabling more efficient power management, enhanced signal processing, and next-generation electronic devices. Whether you're selecting the right capacitor for a project or troubleshooting circuit issues, a solid understanding of these components is essential.

Safety Tip: Always handle capacitors with caution—even when disconnected, they can retain a charge that may pose a hazard. Follow best practices to ensure safe and effective use.

Need a Part? We’ve Got You Covered!

Looking for capacitors or other electronic components? Our experts are here to help! Contact us today for personalized assistance in finding the right part for your needs.