What is a Transformer?

More from the Category

Transformers are the unsung heroes of modern electronics and power systems. From the charger that powers your smartphone to the massive grids that light up cities, transformers play a critical role in ensuring efficient energy transfer. But what is a transformer, and how does this electronic transformer component work?

At its heart, a transformer is a simple yet ingenious device that allows us to step up or step down voltage levels, making it possible to transmit electricity over long distances and power everything from household appliances to industrial machinery. Without transformers, the modern world as we know it — with its sprawling power grids and portable electronics — simply wouldn’t exist.

In this article, we’ll explore the fundamentals of transformers, breaking down how they work, their key components, and the different types that power our world. Whether you’re an engineer designing the next generation of electronics or simply curious about the technology behind everyday devices, this deep dive into transformers will provide valuable insights into one of the most essential components in electrical engineering.

What is a Transformer?

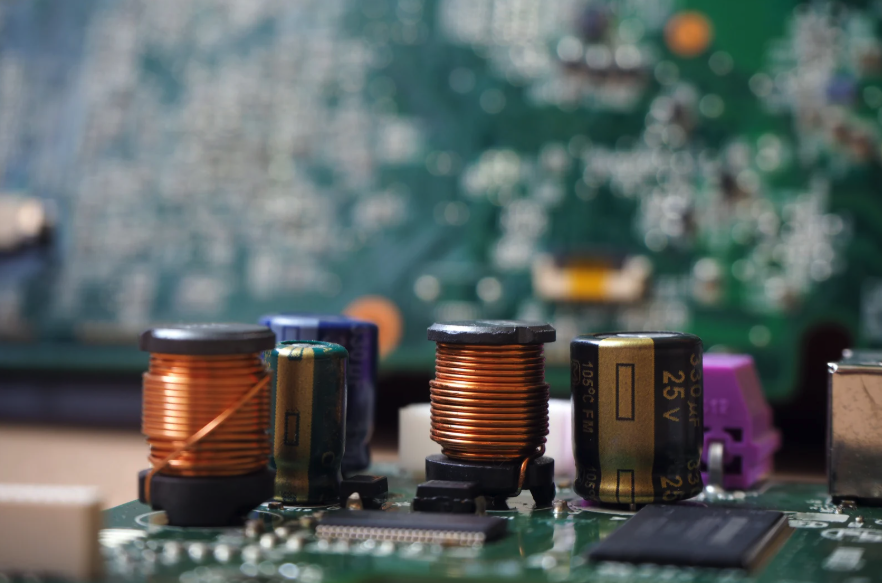

A transformer is an electronic component that transfers electrical energy between two or more circuits through electromagnetic induction. It’s a passive component, meaning it doesn’t generate power but instead modifies voltage and current levels to suit specific needs. At its simplest, a transformer consists of two coils of wire — known as windings — wrapped around a magnetic core. These windings are called the primary and secondary coils, and they work together to step up or step down voltage levels.

Transformers are essential for two key reasons:

Voltage Regulation: They enable the efficient transmission of electricity over long distances by stepping up voltage at power plants and stepping it down for safe use in homes and businesses.

Isolation: They provide electrical isolation between circuits, enhancing safety and reducing noise in sensitive electronic systems.

You’ll find transformers in nearly every corner of modern life. They’re in the power adapters that charge your laptop, the substations that distribute electricity to your neighborhood, and even the renewable energy systems that harness wind and solar power. Without transformers, the delicate balance of our power grids and the functionality of countless electronic devices would collapse.

How Does a Transformer Work?

At the heart of every transformer lies a simple yet profound principle: electromagnetic induction. Discovered by Michael Faraday in the 19th century, this phenomenon is the foundation of how transformers transfer energy without direct electrical contact. Let’s break it down step by step.

The Basics of Electromagnetic Induction

When an alternating current (AC) flows through the primary coil of a transformer, it creates a constantly changing magnetic field around the coil. This magnetic field extends to the transformer’s core, typically made of laminated iron or ferrite, which channels the field efficiently to the secondary coil.

As the magnetic field fluctuates, it induces a voltage in the secondary coil through electromagnetic induction. The key here is that the voltage induced in the secondary coil depends on the ratio of turns between the primary and secondary windings. For example:

● If the secondary coil has more turns than the primary, the output voltage will be higher (step-up transformer).

● If the secondary coil has fewer turns, the output voltage will be lower (step-down transformer).

The Role of the Core and Windings

The core of a transformer serves as the backbone of its operation. Made from materials like laminated iron or ferrite, the core minimizes energy losses by providing a low-resistance path for the magnetic field. Laminations are used to reduce eddy currents, which can cause heat and inefficiency.

The windings, usually made of copper or aluminum, are carefully insulated to prevent short circuits. The primary winding receives the input voltage, while the secondary winding delivers the transformed voltage to the load. The efficiency of this energy transfer is one of the reasons transformers are so widely used — they can achieve efficiencies of 95% or higher in well-designed systems.

Why AC is Essential

Transformers rely on alternating current (AC) because a changing current is necessary to create the varying magnetic field that drives induction. Direct current (DC), which flows in a constant direction, cannot produce this effect. This is why transformers are ubiquitous in AC power systems but require additional components, like inverters, to work with DC sources such as batteries or solar panels.

Key Components of a Transformer

To truly understand how a transformer operates, it’s essential to examine its core components. Each part plays a critical role in ensuring efficient energy transfer, durability, and safety. Let’s dive into the three main elements: the core, the windings, and the insulation.

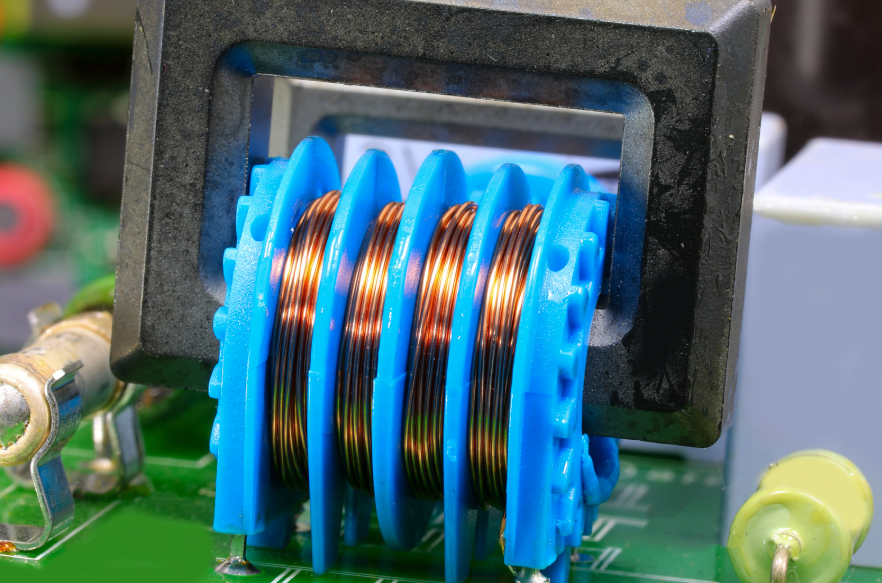

The Core: The Magnetic Backbone

The core is the central structure of a transformer, responsible for guiding the magnetic field generated by the primary winding to the secondary winding. Most transformer cores are made from laminated iron or ferrite, materials chosen for their high magnetic permeability and low electrical conductivity.

● Laminated Iron Cores: These are constructed by stacking thin layers of iron sheets, insulated from one another. The laminations reduce eddy currents — small loops of current induced within the core — which can cause energy losses and heat generation.

● Ferrite Cores: Often used in high-frequency applications, ferrite cores are ceramic compounds that offer low energy loss and excellent magnetic properties. They’re commonly found in transformers for switched-mode power supplies and telecommunications equipment.

The design of the core directly impacts a transformer’s efficiency, size, and weight. For instance, a well-designed core minimizes hysteresis losses (energy lost due to the repeated magnetization and demagnetization of the core material) and ensures smooth magnetic flux transfer.

The Windings: Conductors of Energy

The windings are the coils of wire that carry the electrical current through the transformer. Typically made from copper or aluminum, these coils are wound around the core and come in two types:

● Primary Winding: This coil receives the input voltage and creates the magnetic field when energized by an alternating current (AC).

● Secondary Winding: This coil is where the transformed voltage is induced, delivering the output to the load.

The number of turns in each winding determines the transformer’s voltage ratio. For example, if the secondary winding has twice as many turns as the primary, the output voltage will be double the input voltage. The windings must be carefully insulated to prevent short circuits and ensure reliable operation, especially in high-voltage applications.

The Insulation: Safety and Efficiency

Insulation is a critical yet often overlooked component of a transformer. It serves two primary purposes:

● Electrical Isolation: Insulation prevents direct electrical contact between the windings and the core, as well as between individual turns of wire within the windings. This isolation is crucial for safety and preventing short circuits.

● Thermal Management: High-quality insulation materials can withstand the heat generated during operation, ensuring the transformer remains reliable over its lifespan.

Common insulation materials include paper, varnish, and epoxy resins. In high-power transformers, oil is often used as both an insulator and a coolant, further enhancing performance and longevity.

The Importance of Design and Materials

The choice of materials and the precision of the design directly influence a transformer’s efficiency, size, and cost. For example, using high-purity copper for windings reduces resistive losses, while advanced core materials like amorphous metals can significantly improve energy efficiency.

Types of Transformers

Transformers come in a variety of shapes and sizes, each designed to meet specific needs in power systems and electronics. Understanding the different types of transformers is key to appreciating their versatility and widespread use. Let’s explore the most common categories and their applications.

Step-Up Transformers

Step-up transformers are designed to increase voltage from the primary winding to the secondary winding. They achieve this by having more turns in the secondary coil than in the primary coil.

Applications:

· Power generation plants use step-up transformers to boost voltage for efficient long-distance transmission.

· High-voltage equipment, such as X-ray machines and particle accelerators, also rely on step-up transformers.

Step-Down Transformers

Step-down transformers perform the opposite function, reducing the voltage from the primary to the secondary winding. These transformers have fewer turns in the secondary coil compared to the primary coil.

Applications:

· Household appliances and electronics use step-down transformers to convert high-voltage AC from wall outlets to safer, lower voltages.

· Industrial machinery and control systems often require step-down transformers to match equipment voltage requirements.

Isolation Transformers

Isolation transformers provide electrical isolation between the primary and secondary windings, meaning there’s no direct electrical connection between the input and output circuits.

Applications:

· They are used in medical equipment to ensure patient safety by preventing electrical shocks.

· Audio and video systems use isolation transformers to reduce noise and interference.

Autotransformers

Autotransformers are a unique type of transformer that uses a single winding for both the primary and secondary functions. They are more compact and cost-effective than traditional transformers but offer less electrical isolation.

Applications:

· Voltage regulation in industrial settings.

· Adjustable power supplies and laboratory equipment.

Instrument Transformers

Instrument transformers are specialized devices used to measure high voltages and currents safely. They include:

· Current Transformers (CTs): Step down high currents to measurable levels for monitoring and protection.

· Potential Transformers (PTs): Step down high voltages to safer levels for metering and control.

Applications:

· Power grid monitoring and protection systems.

· Energy metering in industrial and commercial facilities.

Three-Phase Transformers

Three-phase transformers are used in three-phase power systems, which are the backbone of industrial and commercial power distribution. These transformers can handle higher power loads and are more efficient than single-phase transformers.

Applications:

· Industrial machinery and manufacturing plants.

· Large-scale power distribution networks.

Specialty Transformers

Beyond the common types, there are transformers designed for specific applications:

· Pulse Transformers: Used in digital circuits and telecommunications to transmit pulses with minimal distortion.

· Audio Transformers: Found in audio equipment to match impedance and improve signal quality.

· RF Transformers: Used in radio frequency applications for impedance matching and signal coupling.

Choosing the Right Transformer

Selecting the appropriate transformer for a given application depends on factors like voltage requirements, load characteristics, and environmental conditions. Engineers must balance efficiency, cost, and performance to ensure optimal operation. And when it comes time to source the transformers and other components for your next project, you should partner with Microchip USA.

We’re the premier independent distributor of board level electronics, and our team specializes in supplying obsolete and hard-to-find parts — and every component we supply goes through industry leading quality control. Contact us today!