Recycling Semiconductors: The Key to a Greener Tech Future

More from the Category

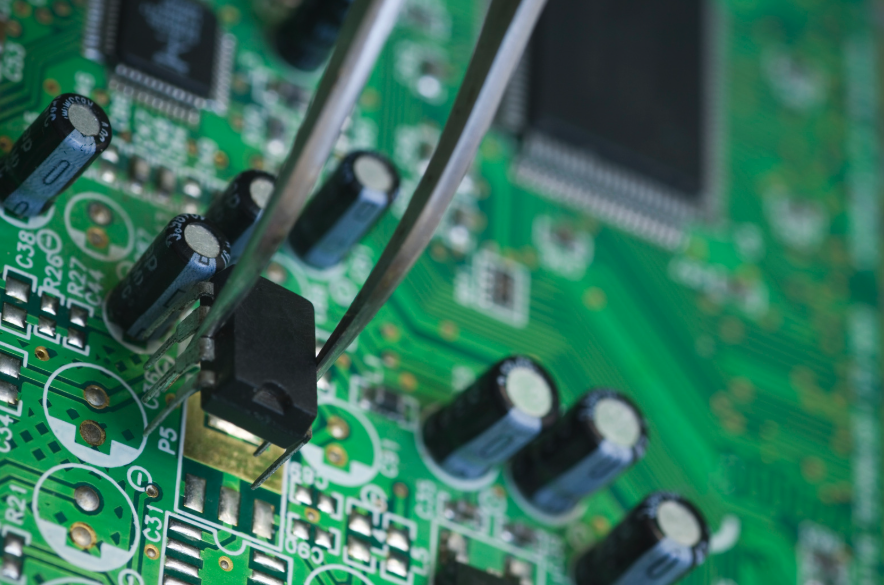

The semiconductor industry has exploded as chips power an increasing number of devices in the modern world, but this rapid technological growth comes with a cost — significant environmental impact. As the demand for electronics increases, so too do questions about sustainability. Chief among them: "Can semiconductors be recycled?"

The process of recycling semiconductors is complex because they combine intricate layers of silicon, metals, and other materials, so their recovery and reuse is challenging. But the stakes are high, and addressing e-waste and resource scarcity is essential for reducing the industry’s environmental footprint and ensuring its long-term sustainability.

This article delves into current recycling techniques, industry challenges, and emerging innovations. As companies strive to close the loop on production cycles, the rise of recycling methods for semiconductor materials offers hope for a more sustainable future.

The Importance of Semiconductor Recycling

With billions of devices manufactured annually, recycling semiconductors has become increasingly relevant. And recycling and reusing semiconductors isn’t just an environmental imperative — it’s an economic and strategic necessity.

Reducing Environmental Impact

Semiconductor manufacturing is resource-intensive and requires large amounts of water, energy, and rare materials. Disposing of end-of-life electronics without recycling leads to growing e-waste, which is not only wasteful but also hazardous. By investing in semiconductor recycling, companies can reduce waste and their carbon footprint, while conserving critical resources like silicon and rare earth metals.

Addressing Resource Scarcity

Materials used in semiconductors — such as gallium, arsenic, and precious metals — are finite, so recovering them is vital for long-term resource security. As global demand for electronics rises, recycling semiconductors ensures a steady supply of these critical elements without overtaxing natural reserves.

Economic and Strategic Advantages

Reclaimed materials can significantly lower production costs by reducing dependence on expensive, newly sourced materials, and countries and companies that adopt advanced recycling technologies gain a strategic edge in resource management and increase the resilience of their supply chain.

Current Techniques for Recycling Semiconductor Materials

The complexity of semiconductors has historically made recycling challenging. However, advancements in technology are offering new solutions to recover valuable materials, and these methods demonstrate how recycling semiconductor materials is becoming increasingly feasible.

Silicon Wafer Recycling

Silicon wafers form the foundation of most semiconductor devices. Recycling these wafers involves processes that restore them for reuse in manufacturing:

● Chemical Etching and Polishing: Used silicon wafers can be chemically etched to remove damaged layers and impurities, and mechanical polishing further smooths the surface for reuse.

● Thermal Treatment: High-temperature processes can restore the structural integrity of wafers and ensure they meet manufacturing standards.

This approach reduces dependency on virgin silicon, which requires significant energy to produce, and allows for a more sustainable production cycle.

Material Recovery from E-Waste

Advanced methods of e-waste recycling are being developed to recover high-value elements like gallium, arsenic, and rare earth metals:

● Hydrothermal-Buffering Techniques: These methods use controlled chemical reactions to extract valuable materials from semiconductor devices. For example, gallium arsenide (used in LEDs and high-speed transistors) can be broken down to recover gallium and arsenic, achieving recovery rates as high as 99.9% and 95.5%, respectively.

● Physical and Chemical Separation: Techniques like shredding, smelting, and acid leaching are employed to separate metals and rare materials from discarded chips and integrated circuits.

Recycling Semiconductor Packaging Materials

The plastic and metal housings that protect semiconductors are also recyclable using pyrolysis (thermal decomposition) to break down components into reusable materials. This reduces waste and allows for the reclamation of secondary materials, such as copper and gold, used in packaging.

Upcycling Damaged Components

Instead of breaking down components entirely, some companies repair and repurpose partially functional chips. These chips can be repurposed for less demanding applications, which extends their lifecycles and reduces waste.

Ultimately, the industry’s ability to scale these methods will determine how effectively it can address the growing environmental impact of semiconductor production and disposal.

Challenges in Semiconductor Recycling

Recycling semiconductors offers significant environmental and economic benefits, but it is far from straightforward. Despite advancements in recycling semiconductor materials, several obstacles make it difficult to scale these processes.

Complex Material Composition

Semiconductors are built from intricate layers of materials, and separating these materials for recovery requires advanced techniques that are both costly and time-consuming. Additionally, modern chips often incorporate new materials and compounds, further complicating the recycling process.

Economic Barriers

Recycling semiconductors is expensive, and the cost of reclaiming materials often exceeds the value of the recovered resources, so companies may find it cheaper to source virgin materials rather than recycle. Moreover, the lack of demand for recycled materials discourages investment in advanced recycling infrastructure.

Lack of Standardization

Each manufacturer uses different designs, materials, and processes, so it’s difficult to establish universal methods for recycling semiconductors. This variability reduces efficiency and increases costs, as recycling facilities must customize their processes for each type of device.

Additionally, inconsistent global regulations make it challenging to streamline recycling efforts. For example, some regions have strict e-waste policies that encourage recycling, while others lack adequate infrastructure or enforcement.

Energy-Intensive Processes

Some recycling techniques are energy-intensive, which reduces their overall environmental benefit — methods like smelting or thermal treatments require significant energy input, which offsets the gains of material recovery.

Limited Awareness and Adoption

Despite the growing importance of sustainability, many companies and consumers remain unaware of the need for and benefits of semiconductor recycling, which slows demand for recycled materials and limits investment in recycling technologies.

Industry Initiatives in Sustainable Practices

Despite the challenges, the semiconductor industry is taking meaningful steps to address the environmental impacts of manufacturing and disposal. Through innovative programs and strategic initiatives, companies are working toward sustainable solutions for recycling semiconductors and integrating environmentally conscious practices into their operations.

Designing for Recycling

Several companies are embracing the concept of "design for recycling," where the recyclability of semiconductor materials is considered during the design phase. By simplifying the material composition of chips and using modular designs, manufacturers can make it easier to separate and recover valuable components at the end of the product's lifecycle.

For example, NXP Semiconductors incorporates sustainability into its design and manufacturing processes. This includes minimizing waste generation and using eco-friendly materials to ensure that products are easier to recycle when they are no longer functional.

Circular Economy Models

Major players like Intel are leading the way in circular economy practices. Intel's sustainability initiatives focus on recovering materials from waste streams and reintroducing them into production cycles. The company emphasizes reducing its environmental footprint by minimizing landfill waste and increasing the reuse of manufacturing byproducts.

Collaboration Across the Supply Chain

The complexity of recycling semiconductor materials has spurred collaboration across the supply chain, and partnerships between chipmakers, material suppliers, and recycling companies are advancing recycling technologies and establishing best practices.

For example:

● TSMC works with suppliers to develop environmentally friendly materials and processes, ensuring that waste generated during semiconductor manufacturing is reused wherever possible.

● Global recycling initiatives, such as the WEEE Directive (Waste Electrical and Electronic Equipment), encourage semiconductor manufacturers to participate in broader e-waste management programs.

Reducing Hazardous Waste

Efforts to minimize the environmental impact of hazardous materials used in semiconductors are another critical focus. Companies like NXP have implemented programs to manage and reduce hazardous waste, ensuring that chemicals used in production are responsibly disposed of or recycled.

Emerging Innovations and the Future of Recycling Semiconductors

As the semiconductor industry confronts the challenges of sustainability, emerging innovations are providing new hope for efficient recycling semiconductor materials. These advancements aim to make recycling more cost-effective, scalable, and environmentally friendly.

Advanced Recovery Techniques

New methods for recovering materials from semiconductors are making recycling processes more efficient and effective. One example is chemical vapor processes that are emerging as a viable method to reclaim silicon from discarded wafers. These approaches remove impurities while preserving the material’s structural integrity, so it can be reused in production.

AI-Powered Recycling Systems

AI algorithms are being used to identify materials in semiconductor components and direct them to the most suitable recycling streams. This technology not only improves material recovery rates but also reduces costs and energy usage.

Modular Chip Designs

To facilitate easier recycling, some manufacturers are exploring modular designs that allow individual components to be removed, replaced, or reused without destroying the entire device. This innovation not only reduces e-waste but also simplifies the process of recycling semiconductor materials by minimizing the need for complex separation methods.

Biodegradable Semiconductors

Researchers are developing biodegradable semiconductors made from organic materials. These devices, designed for temporary use, naturally break down at the end of their lifecycle. While not yet widely adopted, this technology could revolutionize semiconductor recycling by reducing the need for complex recovery processes.

Enhanced Silicon Wafer Recycling

The rise of silicon wafer recycling continues to transform the semiconductor industry. New etching and thermal techniques allow used wafers to be restored with minimal energy input. These innovations not only reduce raw material demand but also lower the environmental impact of silicon production.

Industry-Wide Collaboration

Collaboration between manufacturers, governments, and research institutions is driving the development of advanced recycling technologies. Programs like the European Union’s Circular Economy Action Plan are pushing for stricter regulations and incentives for recycling semiconductor components to promote a more sustainable industry.

Additionally, industry partnerships, such as those facilitated by TSMC and Intel, are accelerating the adoption of sustainable practices and fostering innovation in recycling methods.

Scaling Sustainable Practices

Looking to the future, scaling sustainable recycling practices will be critical. Manufacturers are investing in localized recycling facilities to reduce transportation emissions and make recycling semiconductor materials more practical. Governments are also introducing policies to encourage the adoption of sustainable methods, creating a roadmap for long-term industry transformation.

The Road Ahead

The future of semiconductor recycling lies in combining these innovations with global cooperation and investment. From AI-powered systems to biodegradable components, these advancements promise to reshape the industry, making it more sustainable and resilient. As the question "are semiconductors recyclable?" evolves from uncertainty to action, the semiconductor industry is paving the way for a greener, more efficient future.

If you’re looking to use recycled semiconductor components in your next project, Microchip USA is the perfect partner to source them for you. Whether you need filters, relays, or other integrated circuits, we can deliver them with the best customer service in the industry. Contact us today!