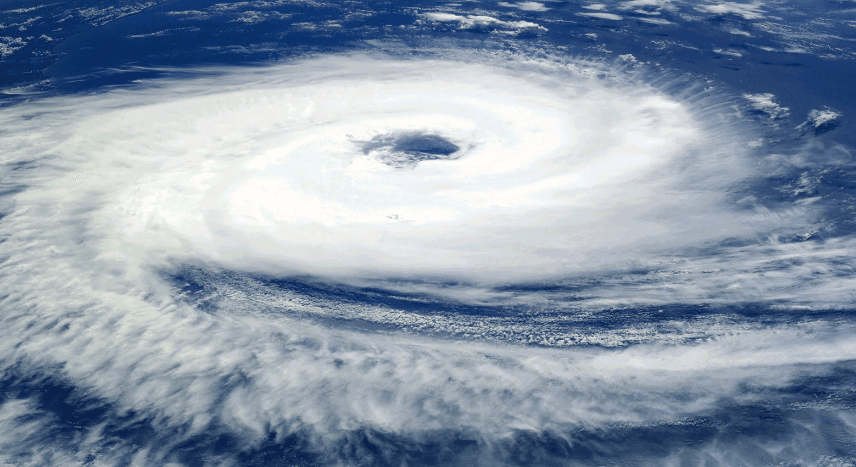

The Effects of Hurricane Helene and Milton on the Semiconductor Industry

More from the Category

Like many industries, the semiconductor industry is highly sensitive to disruptions in its supply chain whether due to geopolitical instability, force majeure, or trade wars. This year, two hurricanes — Hurricane Helene and Hurricane Milton — highlighted just how vulnerable the industry is to natural disasters.

These hurricanes haven’t just disrupted local economies; they have sent shockwaves through the global semiconductor ecosystem, threatening production timelines, inflating costs, and calling into question the long-term stability of silicon-based semiconductors.

This article will explore the technical and market impacts of the hurricanes, highlighting how they have affected the global supply chain and companies worldwide. We’ll also examine how the semiconductor industry might adapt to these increasingly common natural disasters.

Hurricane Helene and the Quartz Supply Chain

One of the most significant impacts of Hurricane Helene is the threat the storm has presented to the supply of high-purity quartz, an essential material in the production of semiconductors. This ultra-pure quartz is a critical element of microchip production because it’s indispensable in the production of silicon ingots — the raw material from which silicon wafers and microchips are made.

High-purity quartz is the material used to fabricate fused quartz crucibles, which are containers that can withstand the incredibly high temperatures of molten silicon. To make a silicon ingot, a fused quartz crucible is filled with melted silicon, then a silicon seed crystal is repeatedly dipped into the crucible until it grows to over 500 kilograms. From there, the silicon ingot is sliced into wafers and those wafers are transformed into microchips using photolithography.

Hurricane Helene hit Spruce Pine, North Carolina — which is home to one the world’s purest quartz mines — particularly hard. While Spruce Pine is a small town of only 2,000 people, the town’s mines are the biggest producer of the quartz used in semiconductor manufacturing in the world, so the global supply chain depends heavily on this region. The purity of quartz from Spruce Pine is unmatched, and any disruption in its availability could lead to lower yields and reduced performance in semiconductor devices.

When Hurricane Helene made landfall, the region received over 2 feet of rain, which caused severe flooding and extensive damage to the regions power grid and infrastructure. Both of the companies that mine quartz in Spruce Pine had to be shut down temporarily due to flooding and structural damage, which has led to immediate concerns over a potential shortage of the material.

The damage to the infrastructure is a particularly big issue, because repairing the roads will take time, especially with the ongoing threat of landslides. And, fixing and replacing damaged mining equipment and transport vehicles will ensure that production won’t return to pre-Helene levels for awhile.

Searching for Alternative Supply Solutions

With access to the material temporarily compromised, many in the industry are scrambling for alternative suppliers — there are other large high purity quartz deposits in India and Brazil. However, the quality and purity of quartz available from other sources often fails to meet the stringent requirements of the semiconductor industry.

Fabricating synthetic quartz is also an option to replace Spruce Pine quartz, but producing the synthetic material is far more expensive, and the current production facilities would be unable to meet the demand if the Spruce Pine mine is shut down for an extended period.

While Hurricane Helene’s impact on the quartz mines of North Carolina has yet to cause global supply chain delays, the possibility of disruption looms large. Most of the semiconductor industry relies on just-in-time manufacturing models, so any disruption in the availability of raw materials can result in delays across the entire production process. With quartz being in short supply, companies may have to adjust their production schedules in the near term and push back the production of crucial components like processors, memory chips, and RF modules.

Currently, many companies have reserves of the material stockpiled, and it’s estimated that it would take a month or more to seriously impact the supply chain. Semiconductor manufacturers, including giants like TSMC and Samsung, normally rely on Spruce Pine quartz to maintain their production lines, though both companies say they are well positioned to weather any disruptions to the supply of quartz coming out of North Carolina.

Ongoing Effects of the Hurricanes

Rising Costs and Price Fluctuations

The disruption in high-purity quartz supply caused prices to surge almost immediately after Hurricane Helene. Quartz is indispensable in producing semiconductor-grade silicon, so any shortage leads to higher costs for wafer production. Companies are left with the tough decision of absorbing the additional costs or passing them on to their customers. As a result, there are those in the industry that expect an uptick in the prices of electronic devices of every sort, from smartphones and smart watches to automotive and medical components.

Impact on Industry Growth and Investments

Both hurricanes have highlighted the risks associated with regional concentration in semiconductor production and material sourcing. With most of the world’s pure quartz coming from a single region in North Carolina, the industry is now reevaluating its dependence on this geographic area. Similarly, the concentration of fabs in storm-prone regions like Texas presents an ongoing risk for the industry.

Some companies are looking to diversify their supply chains and reduce geographic risks by investing in new fabs in more stable regions or by developing alternative materials and techniques to replace high-purity quartz. However, these solutions require significant capital investment and an extended timetable for them to come online. In the short term, these hurricanes have likely slowed the industry’s growth trajectory, with some analysts forecasting a reduction in global semiconductor output for 2024.

Long-Term Implications

The damage caused by Hurricane Helene and Hurricane Milton raises serious questions about the semiconductor industry’s future preparedness for natural disasters. Some of the industry’s key materials and manufacturing facilities are located in geographically vulnerable areas, making the sector particularly susceptible to extreme weather events.

How the Semiconductor Industry Can Adapt

In response to these hurricanes, companies are likely to invest in resilience measures, such as upgrading facilities to withstand flooding, improving supply chain transparency, and diversifying their supplier base. There has also been growing interest in moving some of the most critical fabs and material sourcing operations to regions less prone to hurricanes or other natural disasters.

Another option, according to Minxiang “Glenn” Zeng, an assistant professor in the Department of Chemical Engineering at Texas Tech University, is to explore using materials other than silicon in semiconductors to reduce the industry’s reliance on high purity quartz. According to him, gallium nitride and silicon carbide are alternatives to pure silicon that offer increased efficiency in high-power and high-frequency applications. Also, graphene and metal chalcogenides can be used in nanoscale electronics. Professor Zeng’s research is helping make these alternatives a reality, but they are not yet a viable commercial alternative to silicon, and it could be years before they are.

Shifting Supply Chains

The semiconductor industry might also see a shift in global supply chains as a result of these hurricanes. North America and Asia, particularly Taiwan and South Korea, dominate

semiconductor manufacturing. If natural disasters continue to disrupt these regions, companies might start building more fabs in Europe or other areas less affected by severe weather events. This would be a monumental shift for the industry, but it could ultimately lead to greater stability and fewer disruptions in the long run.

Building Resilience for the Future

The effects of Hurricane Helene and Hurricane Milton on the semiconductor industry underscore the fragility of its supply chains and the vulnerability of key regions and materials. These natural disasters not only disrupted short-term production but also raised critical questions about the long-term resilience of the industry. As the world continues to become more reliant on semiconductors for a wide variety of goods and components in everything from cars to smartphones, the industry must rethink its strategies for handling the growing threat of climate-induced disruptions.

The challenges presented by these hurricanes could spur innovation, encouraging companies to diversify their operations, invest in more resilient infrastructure, and explore alternatives to materials like high-purity quartz. If these alternatives can be turned into reality, the semiconductor industry will emerge stronger and more adaptable in the face of future crises.

And if you’re concerned about being able to source the electronic components you need for your next project, Microchip USA can help! We offer supply chain support services that can find a specific part or manage your supply chain. We have longstanding relationships with an extensive network of suppliers and manufacturers to ensure that we can provide access to whatever components you need. Contact us today!