The World’s First Fully Integrated Silicon Carbide Facility is Here!

More from the Category

STMicroelectronics will begin production of the world’s first fully integrated silicon carbide facility in 2026.

STMicroelectronics

STMicroelectronics is a global semiconductor leader that drives innovation and enables businesses of every scale. ST produces many semiconductor products, including application-specific integrated circuits, memory (including EEPROM), microcontrollers, microprocessors, transistors, and smartcards. Their technologies are key to enabling smarter mobility, enhancing power and energy efficiency, and expanding the deployment of cloud-connected autonomous systems.

The company also employs 50,000 experts who drive innovation in the semiconductor supply chain, supported by advanced manufacturing capabilities. ST collaborates with over 200,000 customers and numerous partners to create solutions, products, and ecosystems that tackle challenges and opportunities while prioritizing sustainability. STMicroelectronics aims to achieve carbon neutrality for scope 1 and 2 emissions, with partial scope 3 neutrality, by 2027.

Highlights

- A new high-volume 200mm silicon carbide manufacturing facility for power devices, modules, testing, and packaging will be established in Catania, Italy.

- The project includes a multi-year investment of 5 billion euros, with 2 billion euros in funding provided by the Italian government under the EU Chips Act.

- The Catania Silicon Carbide Campus will bring ST’s vision of fully integrated SiC capabilities to life, from R&D through manufacturing, all on one site. This facility will support automotive and industrial customers in their transition toward electrification and enhanced energy efficiency.

The New Facility

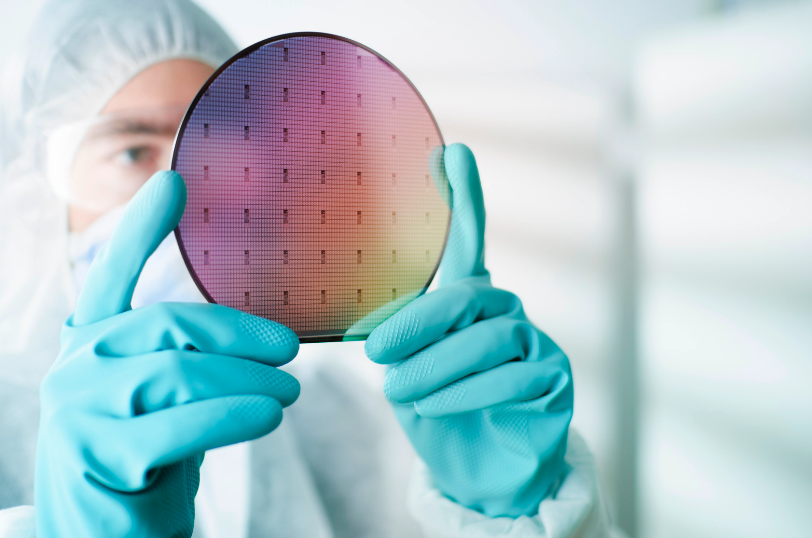

The high-volume 200mm silicon carbide facility for power devices and modules, test, and packaging will be built in Catania, Italy. On the same site, a SiC substrate manufacturing facility is being built, forming STMicroelectronics Silicon Carbide Campus.

The Silicon Carbide Campus will be the center of ST’s global SiC ecosystem, uniting every stage of production—from SiC substrate development and epitaxial growth processes to 200mm front-end wafer fabrication and module back-end assembly. It will also include process R&D, product design, advanced R&D labs for dies, power systems, and modules, along with full packaging capabilities. This will mark a European first for the mass production of 200mm SiC wafers, with every step—substrate, epitaxy, front-end, and back-end—leveraging 200mm technologies to boost yields and performance.

The facility is expected to begin production in 2026, scaling up to full capacity by 2033, with a goal of producing up to 15,000 wafers per week. The total investment is projected to be around five billion euros, with about two billion euros in support from the Italian government under the EU Chips Act. Sustainable practices are embedded in the design and operation of the Silicon Carbide Campus to promote responsible resource use, including water and energy.

Silicon Carbide

Silicon Carbide (SiC) is a key compound material made from silicon and carbon that offers significant advantages over traditional silicon in power applications.

Its wide bandgap and inherent properties make it ideal for high-voltage power devices, especially those above 1,200V. These properties include:

- Better thermal conductivity

- Higher switching speeds,

- Low energy dissipation

SiC power devices, including SiC MOSFETs in bare die form and full SiC modules, are particularly beneficial in:

- Electric vehicles

- Fast-charging stations

- Renewable energy systems

- Various industrial uses like data centers

They deliver higher electric currents and lower leakage than conventional silicon semiconductors, improving energy efficiency.

Supporting the Vision

STMicroelectronics’ vision for a fully vertically integrated manufacturing facility dedicated to the mass production of SiC on a single site is becoming a reality with the establishment of the new Silicon Carbide Campus in Italy. This facility is a key milestone in supporting customers for SiC devices across the automotive, industrial, and cloud infrastructure sectors as they transition to electrification and pursue greater efficiency in SiC device applications.

The President and CEO of STMicroelectronics Jean-Marc Chery stated:

“The fully integrated capabilities unlocked by the Silicon Carbide Campus in Catania will contribute significantly to ST’s SiC technology leadership for automotive and industrial customers through the next decades. The scale and synergies offered by this project will enable us to better innovate with high-volume manufacturing capacity, to the benefit of our European and global customers as they transition to electrification and seek more energy-efficient solutions to meet their decarbonization goals.”

ST’s leadership in SiC stems from 25 years of dedicated R&D, backed by a large portfolio of key patents. Catania, Italy, has been an important site for ST’s innovation, hosting the largest SiC R&D and manufacturing operations and playing a key role in developing new solutions for more efficient and higher performing SiC devices. With a well-established ecosystem in power electronics, including long-term collaborations with the University of Catania and the CNR (Italian National Research Council), along with a vast network of suppliers, this investment will further solidify Catania’s position as a global center of excellence in SiC technology and drive future growth opportunities.

Leading the Future of Silicon Carbide Innovation

The production of the world’s first fully integrated Silicon Carbide Campus marks a significant advancement in semiconductor technology. As the first of its kind, this facility will revolutionize the production of SiC power devices, meeting the increasing demand from automotive, industrial, and renewable energy sectors. By bringing together every stage of SiC production on one site, STMicroelectronics is positioned to lead in the transition toward electrification and enhanced energy efficiency while aligning with global decarbonization goals. The Silicon Carbide Campus strengthens ST’s innovation pipeline and reinforces its commitment to sustainability and technological leadership for decades to come.

Looking for an STMicroelectronics part? Browse our inventory of STMicroelectronics components or speak with an expert for personalized assistance finding the part you need!